-

2022-09-12

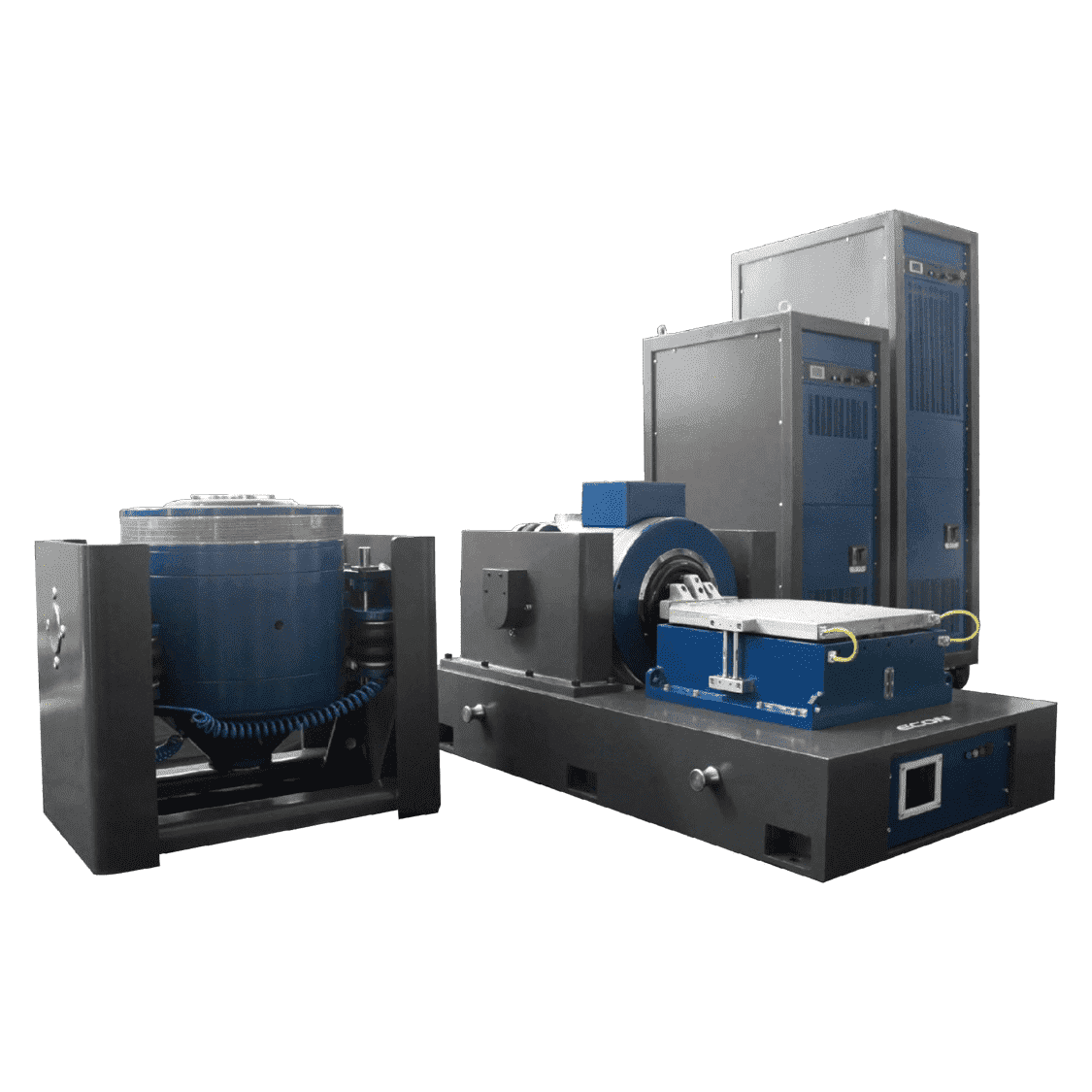

2022-09-12Classification of Vibration Test Machine

Vibration test machine can provide the vibration environment during the manufacturing, transportation and use of the product, identify whether the product has the ability to withstand this environment, for the detection of early faults, simulating the actual working condition assessment and structural strength test. Vibration test machines are widely used in national defense, aviation, aerospace, communications, geotechnical engineering, electronic appliances, automobile manufacturing and other industries. The purpose of vibration testing is to do a series of controllable vibration simulations in the experiment, to test whether the product can withstand the test of transportation or vibration environmental factors in the life cycle, and to determine the requirements of product design and function. Classification of Vibration Test Machine There are 4 main types of vibration test benches:1 Mechanical Vibration Test Machine: convert mechanical energy into kinetic energy.Features: large thrust, poor waveform, low price, suitable for low frequency (5Hz-80Hz) fatigue experiment.2 Electrodynamic Vibration Test Machine: converts electrical energy into kinetic energy.Features: Wide working frequency (from a few Hz to several thousand Hz) good waveform, convenient control, more expensive, is the most commonly used variety of routine tests in the general laboratory. HUD-A521 Simulates Transportation Vibration Test Machine & HUD-G826 High Frequency Electrodynamic Vibration Test System are Electrodynamic Vibration Test Machine. 3 Hydraulic Vibration Test Machine: the hydraulic energy is converted into kinetic energy.Features: low frequency (ultra-low frequency), large thrust, strong load capacity, convenient control, but the upper limit of the working frequency is low (generally tens of Hz to hundreds of Hz as the upper limit), the price is expensive.4 Electro-hydraulic Shaker.The frequency range used is DC to nearly 2000Hz, the maximum amplitude ±500mm, the maximum thrust is 6000kN, and the vibration waveform is sinusoidal, triangular, rectangular, random, can do large-stroke tests, and the size is relatively small compared with the output force (power). Huda provide whole wildly-used vibration test machines. If any inquiry,welcome to us!ReadMore -

2022-09-14

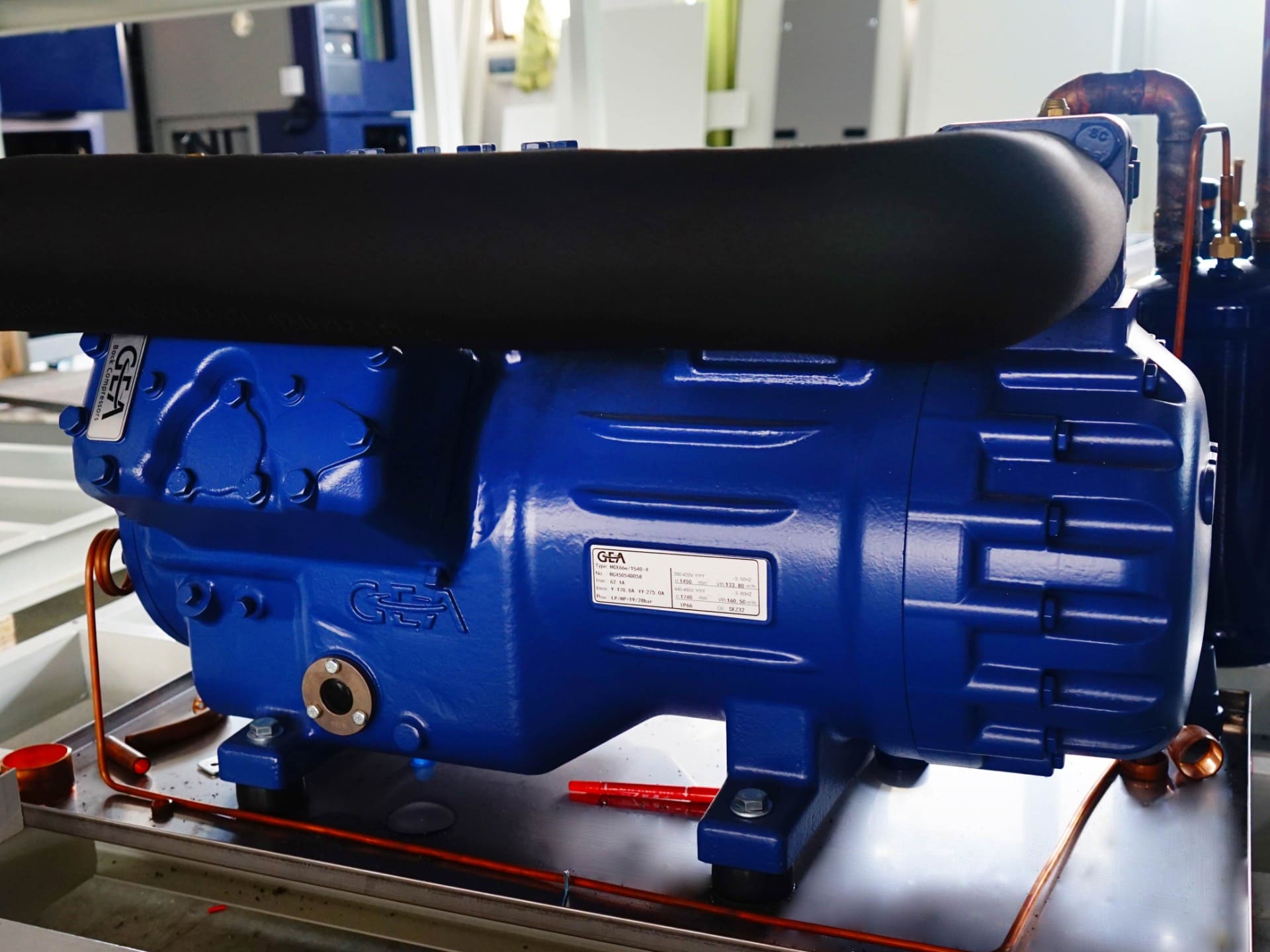

2022-09-14Refrigeration System Working Principle of Temperature and Humidity Test Chamber

Constant temperature and humidity test chamber, also known as high and low temperature humidity test chamber, generally used to test the heat resistance, dry resistance, moisture resistance of electrical, electronic and other products and materials. It is wildly used in aerospace, automotive, scientific research, electronics, electrical appliances, building materials and other fields. Working Principle Of Refrigeration SystemThe compressor is the heart of the constant temperature and humidity chamber’s refrigeration system, it will turn the low temperature and low pressure gas into high temperature and high pressure gas, release heat by condensing into a liquid, take away the heat through the fan, and then through the throttling to the low pressure liquid, followed by the evaporator to become a low temperature and low pressure gas and finally return to the compressor; The refrigerant absorbs heat in the evaporator to complete the gasification process and absorb heat, achieve the purpose of refrigeration, and complete the cooling process. The refrigeration cycle is an inverse carro cycle, which consists of two isothermal processes and two insulation processes.The refrigerant is compressed to a higher pressure by the compressor adiabatic, and the exhaust temperature is increased by the power consumed, and then the refrigerant is isothermal and the surrounding medium is exchanged to transfer the heat to the surrounding medium.The refrigerant is worked by the adiabatic expansion of the interceptor valve, and the refrigerant temperature is reduced.Finally, the refrigerant absorbs heat from the higher temperature object through the evaporator isotherm, so that the temperature of the cooled object is reduced. This cycle repeats itself in order to achieve the purpose of cooling. Huda has more than 18 years experiences in temperature and humidity chamber,provide high quality test machine is always our aim.Please don’t hesitate to contact us if any question about it.CONTACT HUDAReadMore -

2022-09-19

2022-09-19Protective Devices Of Tensile Test Machine

In the case of negligence,tensile test machine will cause the clamps to collide with each other, or the impact force caused by the high-speed impact of the sample will damage the load cell, and even damage the related parts of the machine. Once the machine cannot measure accurate values or the test stops due to damage to the load cell, these will affect the quality of the product. Therefore,tensile test machine have multiple protection mechanisms to ensure the normal operation and long-term use of the machine.Today, huda will show you the protective devices of tensile test machine.1 Power Off ProtectionWhen encountering temporary power failure or power failure caused by thunder, the device will automatically restore the program to the original standby state, which plays an active and effective role in protecting the device. (It's best to turn off the power when the device is not in use or in anticipation of a possible power outage.)2 Limit ProtectionThe tension machine is equipped with upper and lower limit switches, and the limit must be set well before use, which can effectively avoid exceeding the effective stroke during testing, resulting in damage to fixtures, sensors, and even equipment.3 Software ProtectionThe maximum test force: it is used to protect the tensile testing machine from exceeding the specified range and avoid permanent damage to the tensile testing machine caused by overloading.The maximum stroke displacement: it is used to protect the movable parts of the testing machine from exceeding the specified range of the product and avoid the destructive damage to the testing machine caused by over-range use.The maximum deformation: when the deformation value exceeds the set value, the test will be stopped, thus protecting the accessories and equipment.Extracting extensometer: When the deformation of the sample is measured by metal extensometer, when the deformation value is equal to the set value, the test starts to maintain the load and prompts the extraction of the extensometer.4 Safety Protection DoorsThe samples such as rigging, buckles and bolts will fly everywhere at the moment of breaking, and their strength is also relatively large, which will cause a certain degree of damage. After the safety protection door is installed, the protection door is closed during the test, which can protect the stability of the regional environment and the safety of operators to the greatest extent. Huda has more than 18 years experiences in tensile test machine,provide high quality test machine is always our aim.Please don’t hesitate to contact us if any question about it.CONTACT HUDAReadMore -

2022-09-21

2022-09-21Spray System Of Salt Spray Test Machine

Salt Spray Test Machine conducts the salt spray corrosion test through the spray system, so as to test the salt spray corrosion resistance of the protective layers of electronic components, metals and parts. Today we will show you spray system of the Salt Spray Test Machine. 1 Components of The Spray SystemThe spray system is composed of compressed air supply, salt water tank, sprayer and other components. Customer should choose a device that can generate fine, moist and dense mist particles when choosing a sprayer.2 Features of The Spray System(1) The equipment adopts tower sprayer and guide salt spray. The mist particles are small and settle naturally. The nozzle has no salt crystals, and the settling amount is adjustable.(2) The sprayed gas will undergo two-stage voltage regulation and pressure regulation, and at the same time, oil pollution will be filtered and the gas will be humidified and preheated.(3) The atomized salt water storage will be built-in hidden type with large storage capacity, and the salt water will be equipped with a preheating function.(4) The quartz brine filter element is equipped before the brine atomization, which can avoid the impurity clogging of the nozzle and the termination of the test.(5) The air pressure is in the range of 0.2Mpa~0.4Mpa, and the spray pressure is in the range of 0.05Mpa~0.17Mpa.(6) The spraying method of the equipment can be continuous or intermittent spraying and can be adjusted at will. In addition, all the pipes of the test chamber are made of thickened fluorosilicone rubber pipes.Huda has more than 18 years experiences in Salt Spary Test Machine, and provide high quality test machine is always our aim.Please don’t hesitate to contact us if any question about it.CONTACT HUDAReadMore -

2022-09-23

2022-09-23How To Reduce The Possibility Of Explosion Of Lithium Batteries?

The safety of lithium batteries has attracted more attention. However, lithium batteries are prone to failure when the temperature is too high or too low, and in severe cases, explosions and fires may occur.Lithium batteries need to do high and low temperature tests after production. How can we reduce the risk of explosion,when using a battery explosion-proof test chamber to conduct temperature tests on lithium batteries?1. Increase the pressure of the protective gas to keep the pressure of the protective gas inside the equipment shell higher than the pressure of the surrounding explosive environment.2. Filling with sand, filling the shell with sand or other powder materials with specified characteristics, so that under the specified conditions of use, the arc or high temperature generated in the shell cannot ignite the surrounding explosive gas environment.3. Explosion-proof shell, put the parts that may generate sparks, arcs and dangerous temperatures in the flame-proof shell, and separate the internal space of the equipment from the surrounding environment through the flame-proof shell.4. Sealant compound, the electrical components that may generate sparks, arcs or dangerous temperature parts that may cause the explosion of explosive mixtures are sealed in the sealant compound), so that it cannot ignite the explosive mixture.5. The equipment is immersed in the protective liquid, and the entire battery explosion-proof test box or parts of the equipment are immersed in the oil (protective liquid), so that it cannot ignite the explosive gas environment above the fuel surface or outside the casing.6. Test monitoring, set up a remote camera through the explosion-proof window for test monitoring, and detect the surface temperature of each battery. If the battery surface is abnormally heated, it is likely to explode, and the system will immediately activate the safety protection mechanism.Huda has more than 18 years experiences in Temperature Test Machine, and provide whole high quality battery test machine.Please don’t hesitate to contact us if any question about it.CONTACT HUDAReadMore -

2022-09-23

2022-09-23Temperature And Humidity Test Chamber’s Alarm Sound! Why?

Constant Temperature And Humidity Test Chamber is usually used to test the heat resistance, cold resistance, dry resistance and humidity resistance of various materials. Due to the improper operation, it often leads to alarms.There are 3 reasons for the alarm during using.1. Refrigeration System-1- Refrigeration compressor overpressure. If the refrigerant pressure of the refrigeration system exceeds the set value, it will stop and alarm at the same time. At this time, the fault must be eliminated and then reset manually.-2- Circulating cooling water is short of water. When the water pressure of the cooling circulating water system is insufficient, it will stop and alarm at the same time. It must wait for the fault to be eliminated and reset before normal operation.-3- Refrigeration compressor overheating. When the coil of the compressor is overheated and the power supply of the line is abnormal, it will stop and alarm at the same time.2. Temperature System-1- Over temperature in the humid heat alternating cycle test chamber. The sensors in the channel of the test chamber and the sample area are equipped with over-temperature protection devices, and there are also over-temperature protection on the operation panel. When the temperature of the test area exceeds the temperature set on the panel, it will stop and alarm at the same time.-2- Over temperature protection of the test sample. When the temperature of the sample area exceeds the protection temperature set by the controller, it will stop and alarm at the same time. The over-temperature protection of the sample is divided into upper limit protection and lower limit protection, which can be set as required.3. Cooling Fan System-1- Cooling fan overheats. When the coil of the fan is overheated, it will stop and alarm at the same time.-2- Overcurrent of cooling fan. When the current of the fan exceeds the allowable value, it will stop and alarm at the same time, and it can only operate normally after the overcurrent troubleshooting is over.Huda has more than 18 years experiences in Temperature And Humidity Test Machine, and provide whole high quality environment test machines.Please don’t hesitate to contact us if any question about it.CONTACT HUDAReadMore -

2022-09-30

2022-09-30How To Replace The Octagonal Cover In The Battery Burning Test Chamber?

Battery Burning Test Chamber is suitable for the flame resistance test of lithium batteries (or battery packs). It meets GB31241, UL1642, UL2054 and other test standards.Replacement Of The Octagonal Cover The octagonal cover is often damaged during the customer's test and use, and our octagonal cover is detachable on all eight sides. When the aluminum mesh is damaged, just open the corresponding aluminum mesh frame, lay the aluminum mesh on the frame, and then The replacement can be completed by closing the aluminum mesh frame. As shown in the figure:Huda has more than 18 years experiences in Test Machine, and provide whole high quality Battery Test Machines.Please don’t hesitate to contact us if any question about it.CONTACT HUDAReadMore -

2022-10-10

2022-10-10Operation Of Battery Weight Impact Test Machine

Battery Weight Impact Test Machine simulates that the battery (or battery pack) is impacted by free-falling objects of different masses from different heights, resulting in a short circuit inside the battery to evaluate the safety performance of the battery. Operating Steps:1. Confirm that the power supply voltage is 220V, turn on the power switch, and the fan starts randomly;2. Open the door, select the desired impact height, then close the box door tightly, press the "Up" button, the drop weight will automatically rise to the required height limit (the height limit is 610mm or 1000mm), and then automatically stop rising.3. Open the door, insert the safety pin (please follow this step strictly for safety and protection), place the sample to be tested at the center of the pressure plate, and then place the crossbar at the center of the sample clamp the battery, pull out the safety latch, and close the door.4. Press the "Shock" button, the ball drop weight will fall freely to complete a test. Notes:1. The test sample should be a non-deformed sample or a sample with a well-packaged shell, so as not to affect the test conclusion.2. Before placing the sample in each operation, be sure to insert the full-pressing pin. It is strictly forbidden to operate without the safety pin being inserted, so as to avoid unnecessary safety accidents.3. When changing the test height to 1000mm, just loosen the screw of the limit switch at 610mm and remove the limit.Huda has more than 18 years experiences in Test Machine, and provide whole high quality Battery Test Machines.Please don’t hesitate to contact us if any question about it.CONTACT HUDAReadMore -

2022-10-11

2022-10-11How To Avoid The Noise Of The Compressor?

There are 6 ways to avoid the noise of the compressor of temperature and humidity test chamber.1. When the piston hits the exhaust valve during operation, check whether the bolt of the exhaust valve is loose.2. The foundation bolts loosen and vibrate, and the solution to the working principle of the constant temperature and humidity test chamber; tighten the foundation bolts,3. Too much oil causes liquid shock, so check the oil level.4. When the working fluid enters the gas valve to cause hydraulic shock, the expansion valve needs to be closed down or temporarily closed.5. If the valve plate is damaged, replace it with a new one.6. If the bearing is worn, replace it with a new one or carry out maintenance, the intelligent constant temperature and humidity test chamber will be based on the degree of wear.Huda has more than 18 years experiences in Test Machine, and provide whole high quality Temperature and Humidity Test Machines.Please don’t hesitate to contact us if any question about it.CONTACT HUDAReadMore

+86-769-89201493 / 135 0966 8705