-

2023-04-22

2023-04-22Testing Aircraft Components with Altitude Test Chamber

As aircraft technology advances, it becomes crucial to ensure that every component of an aircraft is reliable and withstands extreme pressure and climate conditions that are experienced during flights. This is where Altitude Test Chamber plays a vital role. The Altitude Test Chamber is an essential tool used in testing a wide array of products that are used in aviation.What is an Altitude Test Chamber?An Altitude Test Chamber is a controlled environment designed to simulate various altitude and climatic conditions that aircraft components are subjected to while in the air. The chamber is used to test a wide array of products that include avionics, hydraulic systems, and electrical components. The chamber is designed to provide varying conditions to enable testing and analysis of products to ascertain their reliability in various situations.Advantages of Altitude Test Chamber1. Quality testing - The Altitude Test Chamber helps to determine the quality of products accurately. Components that are tested in the chamber confirm their ability to operate in high altitudes and changing climatic conditions, which is vital in ensuring the safety and reliability of aircraft.2. Cost-effective - With the Altitude Test Chamber, you can easily conduct tests as many times as you wish without incurring additional costs, unlike in real-life flight testing that can be very expensive.3. Time-saving - Testing products can take a lot of time, especially when testing in real-life flight environments. With Altitude Test Chamber, tests can be conducted quickly and without many complications. 4. Provides accurate results - The chamber is designed to replicate different altitudes and climatic conditions, which tests products' ability to perform while maintaining high levels of accuracy. The results generated through this process provide a clear indication of the real-life abilities of the products.Solutions to Common Problems of Altitude Test ChamberThe Altitude Test Chamber, like any other machine, can experience failures that can negatively affect the testing process. Here are some commonly experienced problems and their solutions:1. Humidity control failure - Humidity control is essential in controlling the environment in the chamber. Any malfunction in humidity control can lead to inaccurate results. The solution to this problem is to perform regular maintenance and check-up by trained personnel.2. Temperature control failure - Temperature is another critical aspect of the Altitude Test Chamber. If there is any malfunction in temperature control, the results will be inaccurate. Regular maintenance and check-up is the solution to this problem.3. Pressure control failure - Pressure control in the chamber is essential to replicate the altitude settings accurately. Any malfunction in pressure control can lead to inaccurate results. Regular maintenance and check-up can help prevent this problem.ConclusionIn conclusion, the Altitude Test Chamber is an essential tool that helps to ensure the quality and reliability of aircraft components. It simulates different altitude and climatic conditions that enable accurate testing of aircraft components. This tool helps to save time and costs, making it a valuable investment in aviation technology. The Altitude Test Chamber is not without its challenges, but with regular maintenance and check-up, these problems can be effectively managed. The Altitude Test Chamber remains a vital tool in helping to ensure aviation safety and reliability while advancing aircraft technology.ReadMore -

2023-05-18

2023-05-18Recruit global agents and create a new world in the field of environmental chambers and tensile machines with us!

Finding suitable agents worldwide is an important task for our company, as it will help us expand our business and let more people know about our products. Our company is a professional manufacturer of environmental chambers and tensile testing machine. We have been constantly innovating and improving, and are committed to providing high-quality products and excellent services. Now, we are looking for partners worldwide to be our agents.Our environmental chambers are a high-quality product with suppliers from all over the world. These environmental chambers can be widely used in different fields, including industrial, electronic, medical, and scientific. Our tensile machine can test the tensile and breaking strength of various materials and is widely used in research, manufacturing, and testing fields.As our agent, you will get many benefits. We will provide you with comprehensive training courses to enable you to understand our products and services and learn how to sell and market them. Our training covers technical knowledge of products, sales skills, marketing strategies, and after-sales service. In addition to this, we will provide support and assistance to ensure the success of your business.Our products have a good market demand all over the world. Cooperating with us, you can expand your customer base and help us develop the global market together. We sincerely invite you to join our team, develop together with us, and move towards success together!ReadMore -

2023-08-03

2023-08-03Troubleshooting of common problems in battery combustion test chamber

As technology develops to provide better batteries for our electronic devices, there is a need to ensure the safety of these batteries. Lithium cells and batteries are popular for their high energy density, but can be a safety hazard when abused or subjected to abnormal conditions. To minimize the possibility of failure, these batteries were tested for flame resistance using a battery fire test chamber. However, like most devices, battery burners suffer from technical issues that prevent their use. This blog will shed light on common problems and possible solutions faced when using a battery fire test chamber.1. Chamber overheatingThe battery combustion chamber generates intense heat when the internal battery explodes or catches fire. If the chamber overheats, it will be damaged, resulting in increased repair costs. A malfunctioning cooling mechanism is one of the main causes of overheating. To prevent overheating, make sure the cooling mechanism is working properly and the air filtration system is unobstructed. Clean the filter frequently to promote free air flow and avoid overheating.2.Inaccurate measurementThe battery combustion test chamber is equipped with a temperature sensor and software to measure the temperature and pressure inside the chamber. However, if the sensor fails, inaccurate measurements may occur. To resolve this issue, periodically check the sensor for accuracy. If the sensor is defective, replace it immediately. Also, if the chamber provides fluctuating measurements, recalibrate the sensor to ensure accurate readings.3. Inaccessible dataBattery fire test chambers are often equipped with software to record data such as temperature, voltage and pressure measurements during the test. However, due to the file format, users may experience data inaccessibility. The solution to this problem is to use data logging software in an appropriate format that is compatible with the battery fire test chamber. Make sure the software is regularly updated to the latest version to avoid data corruption and get better results.4. Equipment failureBatteries are constantly being used and therefore wear out over time. Over time, technical failures such as broken wires, damaged sensors or motor problems can occur. When this happens, it must be replaced or repaired to ensure proper operation. A regular maintenance schedule is important and chambers should be routinely inspected, cleaned and calibrated on a regular basis.ReadMore -

2023-07-21

2023-07-21Significance and Function of Battery Thermal Shock Test Chamber

Battery technology continues to advance, shaping the future of countless industries. However, ensuring the safety and reliability of batteries remains a critical issue. To address this issue, the industry relies on innovative testing methods such as battery thermal shock test chambers. In this blog post, we explore the importance and function of these chambers in simulating real-world battery performance.Significance of battery thermal shock test chamber:Battery thermal shock chambers play a vital role in evaluating battery performance and durability under extreme temperature conditions. These chambers can replicate various environmental scenarios, helping manufacturers identify potential problems and improve the quality and reliability of battery products. By thermally shocking batteries, engineers can determine their resistance to sudden temperature changes, ensuring they will perform flawlessly in real-world applications.Learn how it works:The battery thermal shock chamber simulates the exposure of batteries to extreme heat and cold. The simulation helps manufacturers study the impact of temperature fluctuations on battery performance, efficiency and lifetime. By exposing batteries to rapid temperature changes, engineers can better understand the battery's behavior and determine how it will function in harsh environments.process:The test begins by placing the battery in a chamber, which can be a hot box with natural convection or a forced-air system. Set the heating rate and gradually heat the battery to the desired test temperature. Once this temperature is reached, it is maintained for a specific duration. The hot air circulation system in the test chamber ensures an even temperature distribution throughout the battery, providing accurate test results.Analyze performance:Data collected during thermal shock testing of batteries is critical to assessing their performance and safety. It helps manufacturers identify temperature thresholds beyond which batteries may experience reduced efficiency, damage, or potential safety hazards. By identifying these limitations, engineers can make informed design choices and implement necessary modifications to optimize battery performance, reliability and overall safety.Practical application:Battery thermal shock testing is critical in industries where batteries are exposed to extreme temperature changes. This includes electric vehicles, renewable energy storage systems, aerospace and military applications. By subjecting batteries to rigorous temperature cycling, manufacturers can ensure that their products can withstand the rigors encountered in the field, giving both the manufacturer and the end user peace of mind.ReadMore -

2023-08-09

2023-08-09Unleashing the Power of Thermal Cycle Test Chambers Evaluating Product Durability with Precision

In the realm of product design and development, ensuring durability and reliability is paramount. The ability to withstand extreme temperature variations is a vital characteristic that separates exceptional products from the rest. Thus, it becomes imperative for manufacturers to invest in cutting-edge testing methodologies to evaluate the thermal mechanical properties of their products effectively. Step forward, the thermal cycle test chamber – a remarkable invention that harnesses the power of rapid temperature changes to assess and enhance the durability of diverse specimens.Unveiling the Functionality of Thermal Cycle Test ChambersA thermal cycle test chamber is specifically designed to meet the demands of specimens requiring quick and rigorous temperature fluctuations. Through a series of meticulously designed climatic conditions, including holding, cooling-off, heating-up, and drying tests, these chambers meticulously evaluate a product's thermal mechanical properties. By subjecting specimens to such strenuous conditions, manufacturers can identify weaknesses, study their effects, and make informed design or material improvements.Analyzing the Failure PointsThe ultimate objective of any product testing endeavor is to identify potential failure points before they manifest themselves during real-world usage. Thermal cycle test chambers allow manufacturers to simulate the harshest environments that a product might encounter, enabling them to evaluate its thermal resilience under various temperatures. Such evaluations significantly contribute to the longevity of a product, ensuring that it can withstand the test of time, extreme climates, and demanding work environments.Unleashing the Benefits of Thermal Cycle Test Chambers1. Enhanced Product Reliability: Thermal cycle test chambers provide invaluable insights by simulating harsh conditions, enabling manufacturers to make necessary design or material improvements to increase the reliability and durability of their products. This optimization process ensures that products not only meet but exceed customer expectations.2. Saves Time and Money: By thoroughly assessing a product's thermal mechanical properties early in the development process, manufacturers can rectify any potential flaws before mass production. This proactive approach saves both time and money, preventing costly recalls, repairs, or replacements in the future.3. Improved Customer Satisfaction: By subjecting products to rigorous testing and ensuring their ability to withstand demanding environments, manufacturers can confidently offer products that meet and surpass customer expectations. Such reliability lends itself to increased customer satisfaction, loyalty, and positive brand image.4. Research and Development: Thermal cycle test chambers serve as an indispensable tool within research and development departments. They facilitate the development of innovative products that can thrive in extreme conditions, pushing the boundaries of what is possible in numerous industries.In a world where quality, durability, and reliability matter, thermal cycle test chambers have emerged as an essential asset for manufacturers. These chambers provide an efficient and effective means of evaluating a product's thermal mechanical properties, empowering manufacturers to make informed improvements that lead to enhanced durability. By embracing the power of thermal cycle test chambers, manufacturers can unlock a world of opportunities, delivering exceptional products that far surpass customer expectations. So, are you ready to put your products to the thermal endurance test?ReadMore -

2023-08-25

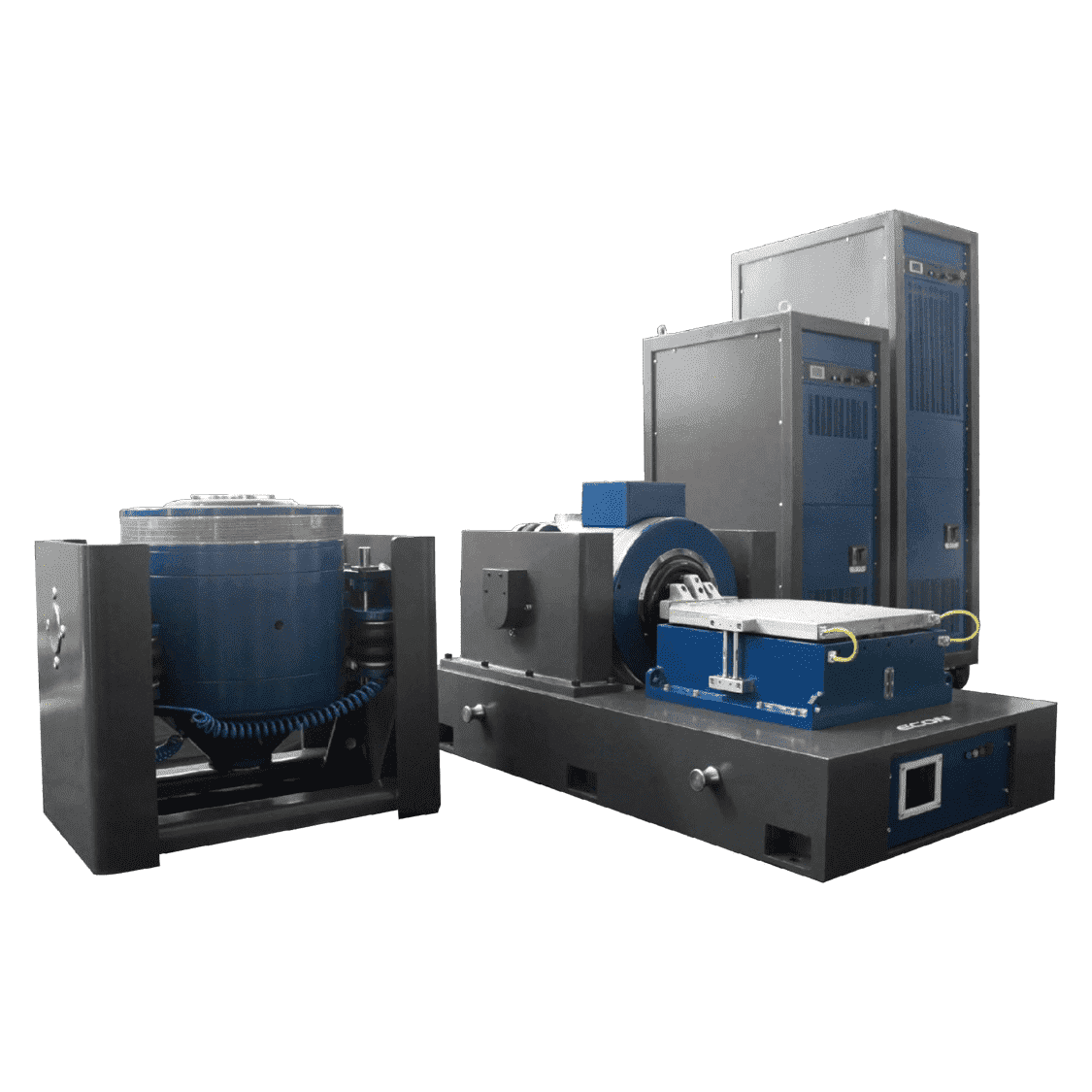

2023-08-25Simulates Transportation Vibration Test Machine

The Simulates Transportation Vibration Test Machine is a state-of-the-art testing equipment designed to evaluate the anti-vibration capabilities of large objects. It allows manufacturers to assess the degree of vibration-resistance in their products, ensuring they are suitable for transportation without compromising their functionality or longevity. Moreover, it aids in ascertaining the quality of packaged products, guaranteeing their safe arrival at the destination.Moving large furniture or appliances from one place to another involves various types of vibrations, including those caused by road conditions or uneven surfaces. These vibrations can place an immense strain on the item being transported, potentially leading to structural damage or loss of functionality. Through the use of the Simulates Transportation Vibration Test Machine, manufacturers can accurately simulate these vibrations and study the resilience of their products.The test machine recreates the motion and vibrations experienced during transportation, allowing manufacturers to identify weak points or areas that require improvement. This invaluable information enables them to refine their designs or select more suitable materials, resulting in sturdier and longer-lasting products. Additionally, it allows manufacturers to meet industry standards and regulations related to the transportation of goods.By subjecting furniture, household appliances, and other large objects to the simulated transport vibration test, manufacturers can enhance the quality and performance of their products. Subsequently, consumers can have confidence in their purchases, knowing that their new furniture or appliance has undergone rigorous testing to ensure its durability.In conclusion, the Simulates Transportation Vibration Test Machine is an indispensable tool for evaluating the anti-vibration capabilities of large objects. It plays a crucial role in assessing the viability of furniture, household appliances, and office furniture for transport, as well as evaluating the resilience of packaged goods. By utilizing this cutting-edge technology, manufacturers can continuously improve the quality of their products, guaranteeing the satisfaction and safety of consumers worldwide.ReadMore -

2023-09-13

2023-09-13Exploring the Power of Thermal Shock Test Chambers in Material Integrity Evaluation

A key aspect of any manufacturing process is determining the extent to which a material can withstand extreme temperature variations. Manufacturers across various industries rely on thermal shock test chambers to assess the performance and reliability of their products. In today's blog, we'll delve deeper into the world of thermal shock test chambers, exploring their purpose, working principles, and the importance of incorporating them into material integrity evaluations.Thermal Shock Test Chamber: Pushing Materials to Their LimitsThe thermal shock test chamber serves as an invaluable tool for examining the bearing capacity of materials and composite structures. By subjecting specimens to instant and continuous exposure to extreme high and low temperatures, this testing equipment allows for rapid assessment of thermal expansion, contraction, chemical changes, and physical harm. With the ability to simulate harsh environmental conditions in the shortest time possible, these chambers provide crucial insights into material durability, helping manufacturers deliver reliable and robust products to their customers.Working Principle: Replicating Real-Life ScenariosThermal shock test chambers are designed to replicate real-life scenarios where materials are exposed to rapid temperature fluctuations. The testing process consists of three chambers: a high-temperature chamber, a low-temperature chamber, and a transition chamber. These chambers are interconnected through a door system that allows for swift transfers of test samples.During the test, specimens are initially placed in a stable environment within the high-temperature chamber. After reaching the desired temperature, the samples are quickly transferred to the transition chamber. Here, the temperature is rapidly changed to simulate a sudden shift. Finally, the samples are moved to the low-temperature chamber to complete the thermal shock cycle. Throughout this process, the chambers provide precise control over the temperature, ensuring accurate and repeatable test results.Why Thermal Shock Testing MattersThe ability of a material to withstand rapid temperature variations is a pivotal factor in product performance and longevity. Thermal shock test chambers enable manufacturers to identify weaknesses in materials, validating their performance in challenging environments. By uncovering potential issues early on, manufacturers can make necessary design modifications, improve material selection, and enhance overall product quality.Industries Benefitting from Thermal Shock TestingThe range of industries benefiting from the incorporation of thermal shock test chambers is vast. Electronics, aerospace, automotive, and consumer goods are just a few sectors where this testing methodology plays a pivotal role. In the electronics industry, for example, thermal shock testing ensures that devices can withstand drastic temperature changes without any adverse effects on functionality or reliability. Similarly, the aerospace industry relies on thermal shock testing to evaluate the performance of materials subjected to varying atmospheric conditions during flight.In conclusion, thermal shock test chambers enable manufacturers to push materials to their limits, ensuring their ability to withstand extreme temperatures and environmental variations. By identifying vulnerabilities early on, manufacturers can improve product quality, longevity, and customer satisfaction. In this era of ever-increasing demands for reliability, these test chambers hold a critical place in material integrity evaluation. Embracing this technology will undoubtedly empower manufacturers to deliver superior products to their customers.ReadMore -

2023-09-21

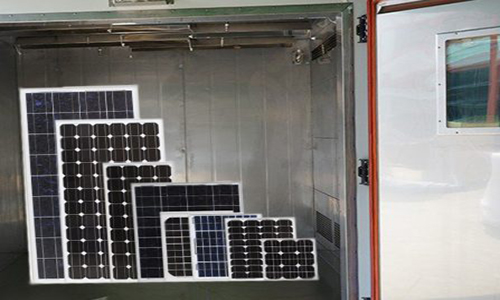

2023-09-21Enhance Solar Panel Efficiency with the Ultimate Test Chamber

As the world becomes increasingly aware of the harmful effects of climate change, the demand for renewable energy sources such as solar power is on the rise. Solar panels, the vital building blocks of solar energy systems, convert sunlight into electricity. To ensure their optimal performance, it is crucial to subject them to rigorous testing. This is where the Solar Panel Test Chamber comes into play.The Solar Panel Test Chamber provides a controlled environment to evaluate various aspects of solar panels, including their response under different light intensities, temperatures, and environmental conditions. By accurately replicating real-life scenarios, researchers and manufacturers gain valuable insights into the panels' efficiency, resistance to extreme weather conditions, and overall reliability.One of the primary functions of a Solar Panel Test Chamber is to determine the efficiency rating of solar panels. Efficiency measures how well a panel converts sunlight into electricity. By conducting tests in a controlled environment, scientists can assess factors such as power output, temperature coefficients, and degradation rates, thereby enabling them to develop more efficient solar panel models.Grid-tied photovoltaic inverters, which convert the direct current (DC) produced by solar panels into alternating current (AC) suitable for household use or grid distribution, also undergo testing in these chambers. By simulating various grid conditions, it is possible to check the inverter's response to voltage fluctuations, frequency regulation, and its ability to synchronize with the grid. These tests ensure that the inverter meets grid standards and operates safely and reliably.Moreover, the Solar Panel Test Chamber serves as an invaluable tool for scrutinizing the performance and durability of photovoltaic cells and modules. Through specialized tests, researchers can evaluate their resistance to extreme temperatures, humidity levels, and other challenging environmental factors. These assessments help manufacturers design solar panels that can withstand harsh conditions, increasing their lifespan and customer satisfaction.ReadMore -

2023-10-12

2023-10-12Unraveling the Power of Random Vibration Test Machines: An Essential Tool for Accurate Product Testing

In the world of product manufacturing, ensuring durability and reliability is paramount to success. Manufacturers are constantly seeking effective methods to simulate real-life conditions and assess their product's resilience. Enter the random vibration test machine – a sophisticated tool that has revolutionized the way products are evaluated and improved.Random vibration testing involves subjecting a product to random vibrations that closely mimic the unpredictable nature of real-world environments. This rigorous testing process helps manufacturers identify potential weaknesses and fine-tune their design and manufacturing processes accordingly.Highlights of Random Vibration Testing1. Realistic Simulation: Random vibration test machines have the ability to quickly and efficiently reproduce a wide range of real-world vibrations, from everyday usage to extreme conditions. It accurately mimics vibrations encountered during transportation, rough handling, or even seismic activities, ensuring that products can withstand any environment they may encounter.2. Increased Product Reliability: By subjecting products to controlled random vibrations, manufacturers can identify structural weaknesses and potential failures before they reach the market. This testing approach helps increase product reliability and lifespan, reducing the risk of premature failures and costly recalls.3. Design Optimization: Random vibration testing provides invaluable insights into optimal design improvements. By analyzing the behavior of prototypes, manufacturers can enhance their product's structural integrity, minimize weak points, and optimize materials and components, leading to overall improved performance.Applications of Random Vibration Testing Machine1. Aerospace and Defense: The aerospace and defense industry relies heavily on random vibration testing to ensure the robustness of critical components such as avionics systems, rocket engines, and military-grade equipment. This testing simulates the extreme conditions faced during launch, aerial maneuvers, or harsh environments, guaranteeing the endurance and safety of these crucial systems.2. Automotive Industry: Random vibration testing plays a vital role in the automotive industry, where products need to withstand a variety of road conditions and maintain performance over time. Testing components like engines, suspensions, and electronic systems under random vibrations ensures their reliability and longevity, leading to safer and more durable vehicles.3. Consumer Electronics: From smartphones to home appliances, random vibration testing is crucial to guaranteeing the durability and overall quality of consumer electronics. This testing helps identify and rectify weaknesses, ensuring our devices can endure everyday wear and tear, transportation, and accidental drops.ReadMore

+86-769-89201493 / 135 0966 8705