-

2022-10-14

2022-10-14Chinese Electric Blankets Sell Well In Europe

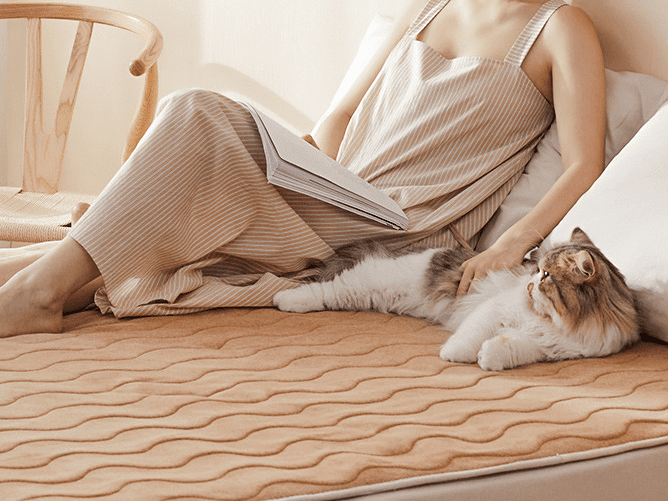

Recently, in a video speech, French President Emmanuel Macron wore a turtleneck sweater instead of a western-style shirt. According to related reports, Macron is leading by example, calling for a reduction in energy use in winter and a joint response to the European energy crisis.This year, many Chinese-made "winter artifacts" appeared in the winter of Europe. From electric blankets, down jackets, to electric gloves and hand warmers, and now to turtleneck sweaters...According to data from the General Administration of Customs, in July, 27 EU countries imported 1.29 million electric blankets from China, a month-on-month increase of nearly 150%. Among them, Germany imported 419,000 electric blankets, and the United Kingdom imported 582,000 Chinese electric blankets.From January to July 2022, the export value of my country's electric blankets to Europe reached 33.4 million US dollars, a year-on-year increase of 97%. Specifically, the export growth rate of electric blankets to major European countries was 77.2% in the UK, 129.8% in the Netherlands, 135.6% in Germany, 191.4% in Poland, 338.1% in Italy and 372.6% in Greece."The cost of electricity per penny/kWh in October 2022 was around 52p. If the most common electric blanket with a power of about 100W is calculated, it costs less than 5p for an hour, and less than 40p for a whole night (8 hours), which is 1/16 of the cost of general electric heating, and also There are some less energy-efficient electric blankets that claim to cost as little as 1p to use overnight."I know it will save me some heating bills. A warm bed is a luxury now," wrote a consumer who bought an electric blanket. Another said a Chinese-made electric blanket is perfect for cold nights .Whether it is a rechargeable electric blanket or other heating equipment, as long as the products of household appliances are exported to EU countries, CE certification is required, and CE marks are required to be affixed on the products.These heating devices require special attention to temperature, humidity and electricity safety.At this time, Temperature and Humidity Test Machine can accurately control the impact of temperature and humidity on such products and components, and contribute to product quality improvement and safety.Huda has more than 18 years experiences in Test Machine, and provide whole high quality Temperature and Humidity Test Machines.Please don’t hesitate to contact us if any question about it.CONTACT HUDAReadMore -

2022-10-18

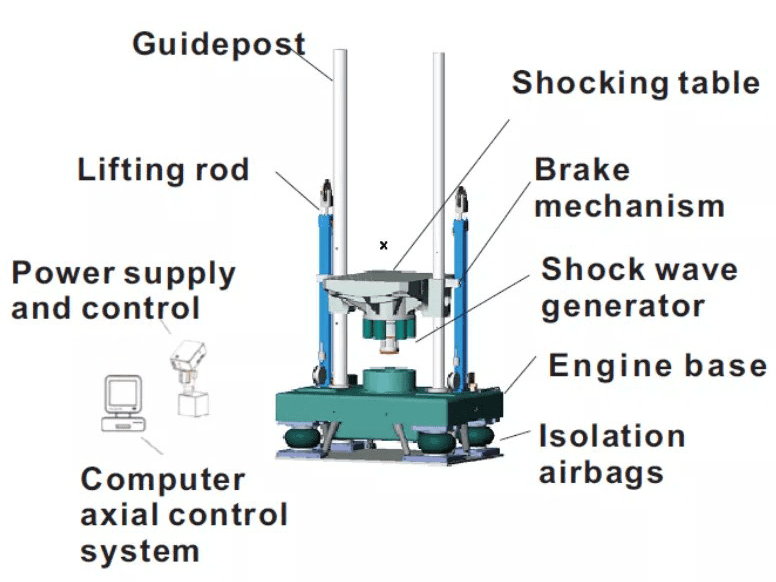

2022-10-18Advantages of Mechanical Shock Test System

1. Windows-based stability control system, fully automatic remote control interface.2. Multi-track guide column combined with good lubricity and noiseless hydraulic balance lifting system to achieve stable gear shifting.3. Automatic control of lifting height, high precision and good repeatability.4. Using high-strength and high-hardness cast aluminum countertop, high first-order resonance frequency, low noise, no clutter.5. Built-in brake mechanism to avoid secondary rebound collision and safer positioning table.6. Multiple waveforms: can perform conventional half-sine wave, rear peak sawtooth wave or trapezoidal wave.7. Self-contained cushioning vibration isolation base, no need for special foundation, easy to install.8. One-stop test: The built-in test standards meet various requirements and help users complete the test in one stop.Huda has more than 18 years experiences in Test Machine, and provide high quality Mechanical Shock Test System.Please don’t hesitate to contact us if any question about it.CONTACT HUDAReadMore -

2022-10-21

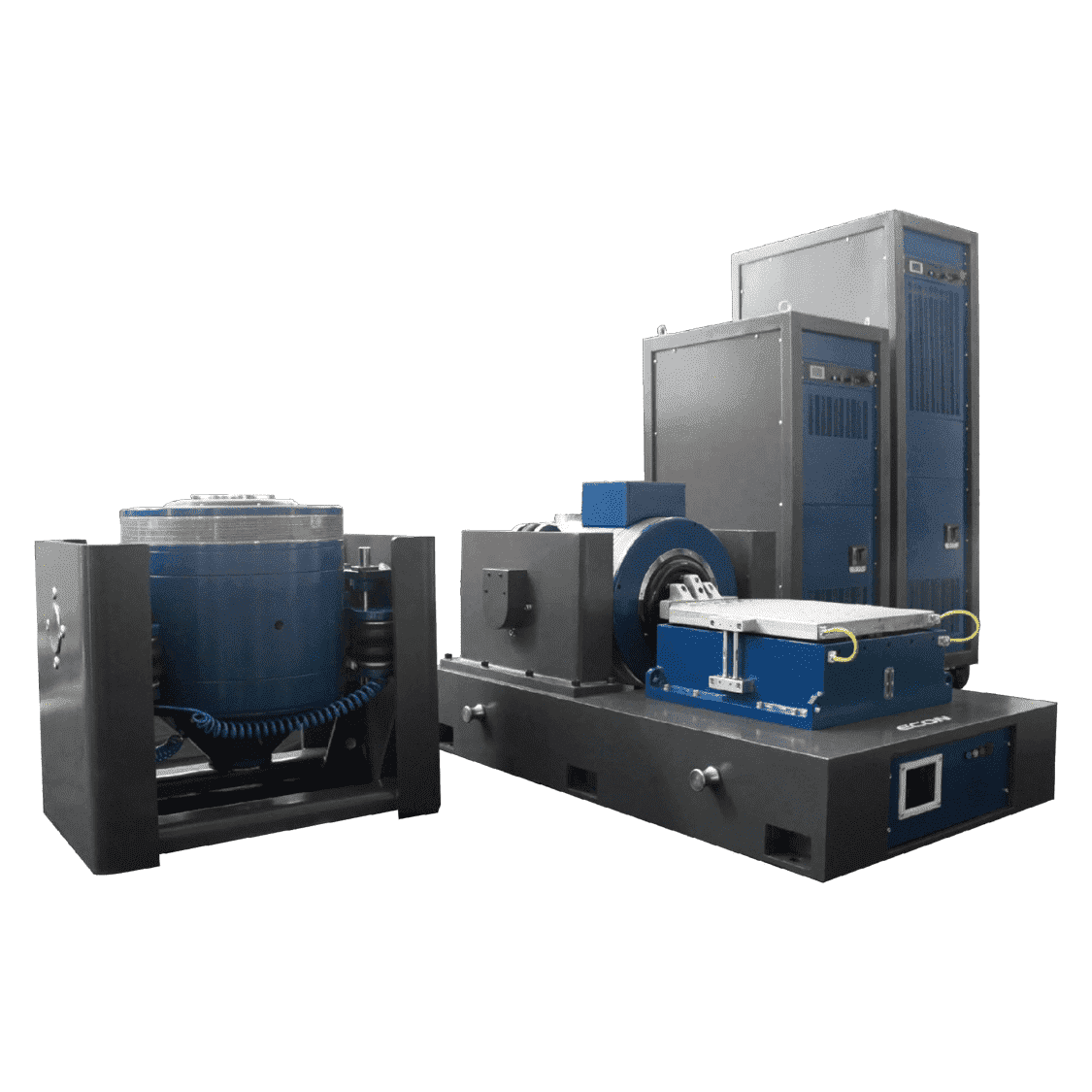

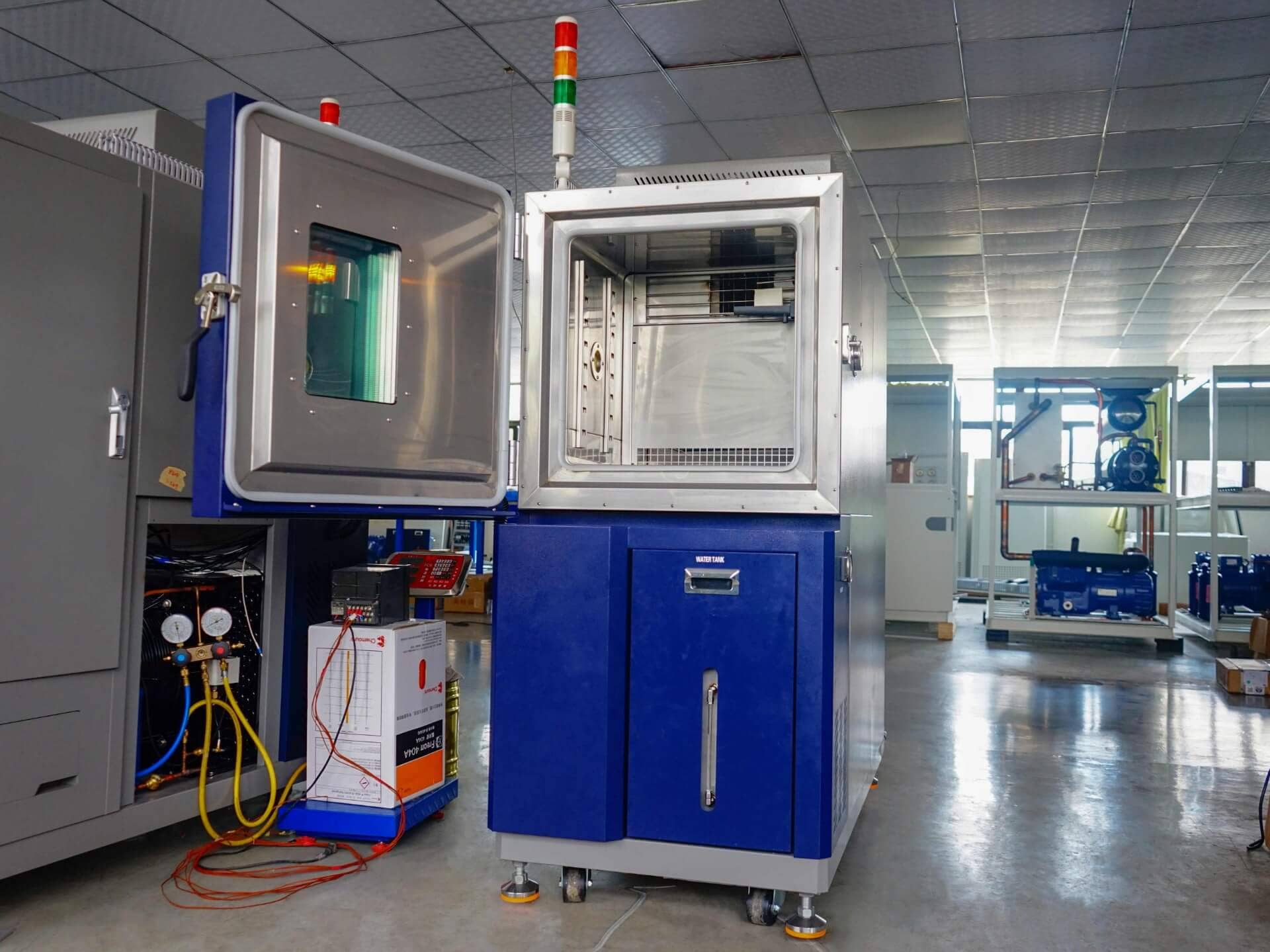

2022-10-21Environmental Test Chamber Of Huda

Huda test chambers are available in a variety of configurations that can meet your temperature, humidity, altitude, vibration, and salt spray testing requirements.Huda has more than 18 years experiences in Test Machine, and provide high quality Environmental Test Machine.Please don’t hesitate to contact us if any question about it.CONTACT HUDAReadMore -

2022-10-26

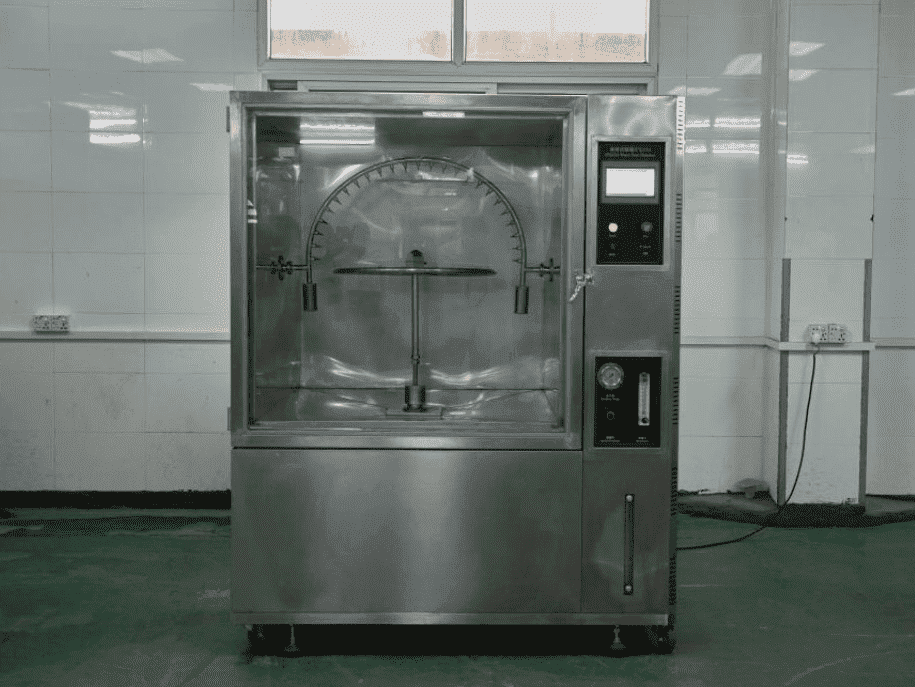

2022-10-26What Will Effect IP Test?

IP test chamber can simulate various environments such as the rain and water spraying test that electronic products and their components may be subjected to during transportation and use. It is suitable for the protection of external lighting,signal devices and the shell of automobile lamps. Different products need to do different tests, IP test chamber protection level (IP test) is also different. Ingress Protection is the full name of IP. IP level is the protection level of the shell of electrical equipment against foreign body invasion. It comes from the standard IEC50529 of the International Electrotechnical Commission, which was also adopted as the national standard of the United States in 2004. The IP level is composed of two numbers. The first number dust resistance. The second number indicates waterproof. The higher the number, the better the protection. Generally speaking, the IP test is affected by 3 elements: placement, water temperature and water pressure. 1 PlacementDuring the test, the test time directly affects the rationality of the test results, and if the test time is too long, it does not conform to the natural rainfall. If it is too short, the rain cannot enter the tested products and cannot achieve the effect of assessment. In addition, in the case of natural rainfall, the direction of each rainfall could not be the same, which made the surface of the subject products under different conditions of rain, so we put the subject products in the normal use state during the test. 2 TemperatureWhen it rains naturally, the rain can adjust the temperature, so the temperature of the rain will not be too high to the ground. When the test is conducted according to the standard test conditions, the temperature of the water does not have to be controlled, but the temperature of the water should be as close as possible to the temperature of the tested product, so as to reduce the possibility of condensed water inside the tested product. 3 Water PressureThe pressure of the waterproof test chamber is supplied by tap water. When the pressure is large, it is small and fluctuates greatly. The pressure stabilizing device should be used to keep the water pressure stable.Huda has more than 18 years experiences in Test Machine, and provide high quality IP Test Machine.Please don’t hesitate to contact us if any question about it.CONTACT HUDAReadMore -

2022-11-03

2022-11-03How To Solve The Problems Of Constant Temperature And Humidity Test Chamber?

When constant temperature and humidity test chamber have some problems during using,what we can do to solve it?1. Water LeakageSolution: Install pressure balance port to ensure consistent pressure inside and outside the box and solve the problem of water leakage 2. High Pressure Alarm A: the test environment temperature of the air-cooled constant temperature and humidity is too highSolution 1: It is recommended that the customer's ambient temperature<30°C (usually controlled at 20-27°C)B: the circulation fan is faulty, the circuit board capacitor that controls the fan is faulty, causing the speed to not meet the standard, and the temperature is too high, resulting in an alarmSolution 2: Change the circulating fan 3. The Entrance Of The Painted Water Tank Is Easy To RustSolution: Communicate with the paint shell supplier to improve the stainless steel treatment 4. Compressor NoiseSolution: The bottom is not sealed, only a fixed frame or customer non-standard requirements, increase the thickness of the plate 5. Evaporator Is FrostedSolution: An additional evaporating pressure regulating valve is required to increase the evaporating pressure on the surface of the evaporator, so as to control the evaporating temperature and prevent frostingIf some other problems or you cannot solve these issues,please contact us to help you.Huda has more than 18 years experiences in Test Machine, and provide high quality Environment Test Machine.Please don’t hesitate to contact us if any question about it.CONTACT HUDAReadMore -

2023-08-08

2023-08-08Xenon Lamp Aging Test Machine

Xenon Lamp Aging Test Machine simulates the damages caused by sunlight and weathers when the material exposed to high temperatures and light. Use light tubes to simulate the effects of sunlight and reproduce damage that can take months or even years outdoors, including fading, color changes, tarnishing, chalking, cracking, cracking, wrinkling, blistering, brittleness. Applications:Xenon Lamp Aging Test Machine is mainly used for aging test for automobiles and parts, plastics, instrument panels, steering wheels, bumpers, etc., and meet the testing needs of new energy, photovoltaic,solar energy and other industries. Test Standards:①PR 306.5②GJB150.7-86③JB150A.7-2009④IEC60068-2-5⑤GB2423.24⑥DIN75220⑦MIL-STD 810GHuda has more than 18 years experiences in Test Machine, and provide high quality Xenon Lamp Aging Test Machine.Please don’t hesitate to contact us if any question about it.CONTACT HUDAReadMore -

2023-08-05

2023-08-05Detailed introduction of high temperature aging test chamber

一、High temperature aging test Chamber body structure1. The bottom seat of the high-temperature UV Aging Test Chamber is welded with 8# channel steel mesh structure, which has strong bearing capacity and can avoid the unevenness and cracking of the bottom2. The cabinet is formed by CNC machine tools, with beautiful appearance and non-reactive handles, which is easy to operate3. The inner liner of the box is made of imported stainless steel (SUS304) mirror panel, and the outer liner of the box is sprayed with A3 steel plate, which increases the appearance texture and cleanliness4. The large observation window is equipped with lighting to keep the inside of the box bright, and the built-in tempered glass in the heating element is used to clearly observe the conditions inside the box at any time5. The observation window is made of multi-layer tempered glass, and there is a defrosting device in the window to ensure a good observation field of view, so as to monitor the test situation at any time6. The circuit system adopts door opening, which is convenient for maintenance and repair7.The box body insulation adopts ultra-fine glass fiber insulation cotton, which can avoid unnecessary energy loss二、Performance characteristics of high temperature aging test chamber1. Accurate temperature control and high precision. Due to the unique air duct system design and electronic control system, it can maintain the temperature uniformity of the whole room, which is much higher than that of similar products.2. The system has complete protection functions, which can ensure long-term stable and trouble-free operation.3. Ultra-fine thermal insulation cotton is filled between the outside of the box and the inner tank, which has a good temperature insulation effect and effectively reduces the temperature fluctuation rate in the test box, and cooperates with the tight sealing of the anti-aging silicone rubber sealing strip to make the box free of fog Leakage occurs4. The hot air circulation system is composed of a fan and a special air duct that can operate continuously at high temperatures, and the temperature in the working room is uniform.三、Functional characteristics of high temperature aging test Chamber1. There is a test hole with a diameter of 50 mm on the left side of the box, which can be used for external test power lines or signal lines. The box is specially equipped with a test hole with a diameter of 50 mm, which can be connected to recorders, printers and computers.2. The temperature control adopts fully imported touch button instrument, which is easy to operate and set.3. It has the function of P.I.D automatic calculation, which can immediately correct the temperature change conditions and make the temperature control more stable.4. After the data and test conditions are input, the controller has a locking function to avoid changing the temperature value due to human touch.Independent temperature limit alarm system, automatically interrupted when the temperature exceeds the limit, to ensure that the experiment runs without accidents. There is a large-area tempered glass observation window for observing the status of the studio.四、Operation process of high temperature aging test chamberThe following describes the three major setup processes.1. Track alarm temperature setting Before the product leaves the factory, the high temperature of 10°C is already reluctant, so it is generally not necessary to set it. If you need to reset, press the function key 'SET' for 5 seconds, the meter enters the upper limit tracking platinum setting and hits 'AL1', then press the shift key to cooperate with the plus or minus key to operate, and then press the function key 'SET' to confirm, The tracking alarm setting is completed.2. Use of PID self-tuning If you have higher requirements on the fluctuation of temperature control accuracy, you can use PID self-tuning custom control. When the temperature in the box is about to reach the set temperature, first press the function key 'SET' for 5 seconds, the meter enters the setting cycle state 'AL1', continue to press the 'SET' key to use the PV window to display 'ATU', and the SV display '0000' 'Then press the plus key SV to display '0001', then press the function key 'SET' to confirm, at this time the light is on when the value is self-tuning, and the controller enters PID self-tuning control3. Temperature display value correction Since the front waist of the product has been strictly tested before leaving the factory, it is generally not necessary to make corrections. If the cycle is not good when the product is in use, and the external temperature is too low or too high, it will cause an error between the temperature display value and the actual temperature in the box. If it exceeds the technical indication range, you can correct the specific steps; press the function key SET for about 5 seconds, it is the instrument Enter the parameter setting cycle state 'AL1', continue to press the function key 'SET' to make the PV display 'SC' correction, and then press the shift key to cooperate with the plus or minus key to perform temperature correction. Then press the SET key to confirm, and the correction of the displayed temperature value is completed.ReadMore -

2023-02-16

2023-02-16Exploring the Benefits and Uses of Environmental Test Chambers

Environmental test chambers are a type of equipment used in scientific and industrial research to simulate various environmental conditions, such as temperature, humidity, and light. These chambers are used to test the performance and durability of materials, products, and components under specific environmental conditions. Environmental test chambers are essential tools for a wide range of industries, including automotive, aerospace, electronics, and pharmaceuticals. This feature article will explore the different types of environmental test chambers, their applications, and how they contribute to environmental sustainability.Types of Environmental Test ChambersThere are different types of environmental test chambers, including temperature chambers, humidity chambers, vibration chambers, and thermal shock chambers. Temperature chambers are designed to test the effect of different temperatures on a product or component. These chambers can simulate a wide range of temperatures, from -70°C to 180°C, depending on the type of product being tested. Humidity chambers, on the other hand, are used to test the effect of different humidity levels on a product or component. These chambers can simulate humidity levels ranging from 10% to 95%.Vibration chambers are used to test the impact of mechanical vibrations on products or components. These chambers can simulate different types of vibrations, including sinusoidal, random, and shock vibrations. Thermal shock chambers, on the other hand, are designed to test the effect of sudden temperature changes on a product or component. These chambers can quickly transition a product from extreme cold to extreme heat, simulating real-world conditions that products may face during transportation or use.Applications of Environmental Test ChambersEnvironmental test chambers have a wide range of applications in various industries. For example, in the automotive industry, environmental test chambers are used to test the durability and performance of automotive components, such as engines, brakes, and suspension systems, under extreme temperatures and humidity levels. In the aerospace industry, these chambers are used to test the impact of different environmental conditions on aircraft components, such as avionics and engines.In the electronics industry, environmental test chambers are used to test the reliability and performance of electronic components and devices, such as smartphones, laptops, and other electronic gadgets. In the pharmaceutical industry, these chambers are used to test the stability and efficacy of drugs under different environmental conditions, such as temperature and humidity.Contribution to Environmental SustainabilityEnvironmental test chambers play a crucial role in promoting environmental sustainability in various industries. By testing the durability and performance of products under different environmental conditions, manufacturers can design and produce more sustainable and eco-friendly products. For example, in the automotive industry, environmental test chambers can be used to test the performance of electric vehicles under extreme temperatures and humidity levels, helping manufacturers to design more reliable and efficient electric vehicles.In the electronics industry, environmental test chambers can be used to test the durability and reliability of electronic gadgets, such as smartphones and laptops, under extreme environmental conditions, reducing the need for frequent replacements and contributing to the reduction of electronic waste. In the pharmaceutical industry, environmental test chambers can be used to test the stability and efficacy of drugs under different environmental conditions, ensuring that the drugs are effective and safe for use.ConclusionIn conclusion, environmental test chambers are essential tools for a wide range of industries, including automotive, aerospace, electronics, and pharmaceuticals. These chambers are used to simulate different environmental conditions, such as temperature, humidity, and vibration, and test the performance and durability of products and components. Environmental test chambers play a crucial role in promoting environmental sustainability by helping manufacturers design and produce more sustainable and eco-friendly products. As technology advances, we can expect to see more innovative and advanced environmental test chambers that will continue to play a vital role in scientific and industrial research.ReadMore -

2023-08-28

2023-08-28Universal tensile machine common problem solution

The universal tensile machine is an essential piece of equipment in materials testing labs that measures the tensile strength of various materials. However, like any other machine, it can experience common problems that can affect its accuracy and performance. In this article, we will explore the solutions to some of these common problems.Inaccurate Readings: One of the most common problems with the universal tensile machine is inaccurate readings. This can be caused by several factors, including incorrect calibration, worn-out grips, or a malfunctioning load cell. To solve this problem, the machine should be regularly calibrated using the appropriate calibration standards. The grips should also be inspected and replaced if worn out. Finally, the load cell should be checked for proper functioning and replaced if necessary.Slipping Specimens: Another common problem is slipping specimens. This occurs when the specimen slips out of the grips during the testing process, resulting in inaccurate readings. To prevent this, it is important to ensure that the grips are properly tightened to hold the specimen securely in place. Additionally, using grips with serrated surfaces can help increase friction and prevent slipping.Specimen Damage: Sometimes, specimens can be damaged during testing, leading to inaccurate results. This can happen if the specimen is not properly prepared, or if the grips are too tight. To prevent this, it is important to properly prepare the specimen, including cutting it to the correct size and shape, and using the appropriate grips. It is also important to ensure that the grips are not too tight, as this can cause damage to the specimen.Software Malfunction: Another common problem with the universal tensile machine is software malfunction. This can be caused by a variety of factors, including corrupted software, outdated drivers, or hardware failure. To solve this problem, it is important to ensure that the software is up-to-date and that all drivers are properly installed. Additionally, the hardware should be checked for any signs of damage or malfunction.Overloading: Overloading the machine can cause damage to the load cell and other components, leading to inaccurate readings and reduced lifespan of the machine. To prevent overloading, it is important to use the appropriate load cell for the specimen being tested and to follow the manufacturer's guidelines for maximum loads.Maintenance Issues: Regular maintenance is important for ensuring the optimal performance and accuracy of the universal tensile machine. Neglecting to perform regular maintenance, such as lubrication, cleaning, and inspection, can lead to a variety of problems, including inaccurate readings and reduced lifespan of the machine. To prevent these problems, it is important to follow the manufacturer's guidelines for maintenance and to perform regular inspections and maintenance tasks.In conclusion, the universal tensile machine is a valuable piece of equipment in materials testing labs. However, like any other machine, it can experience common problems that can affect its accuracy and performance. By following the guidelines outlined in this article, including regular maintenance, proper specimen preparation, and the use of appropriate grips and load cells, it is possible to prevent and solve many of these problems and ensure accurate and reliable results from the machine.ReadMore

+86-769-89201493 / 135 0966 8705