-

2024-08-30

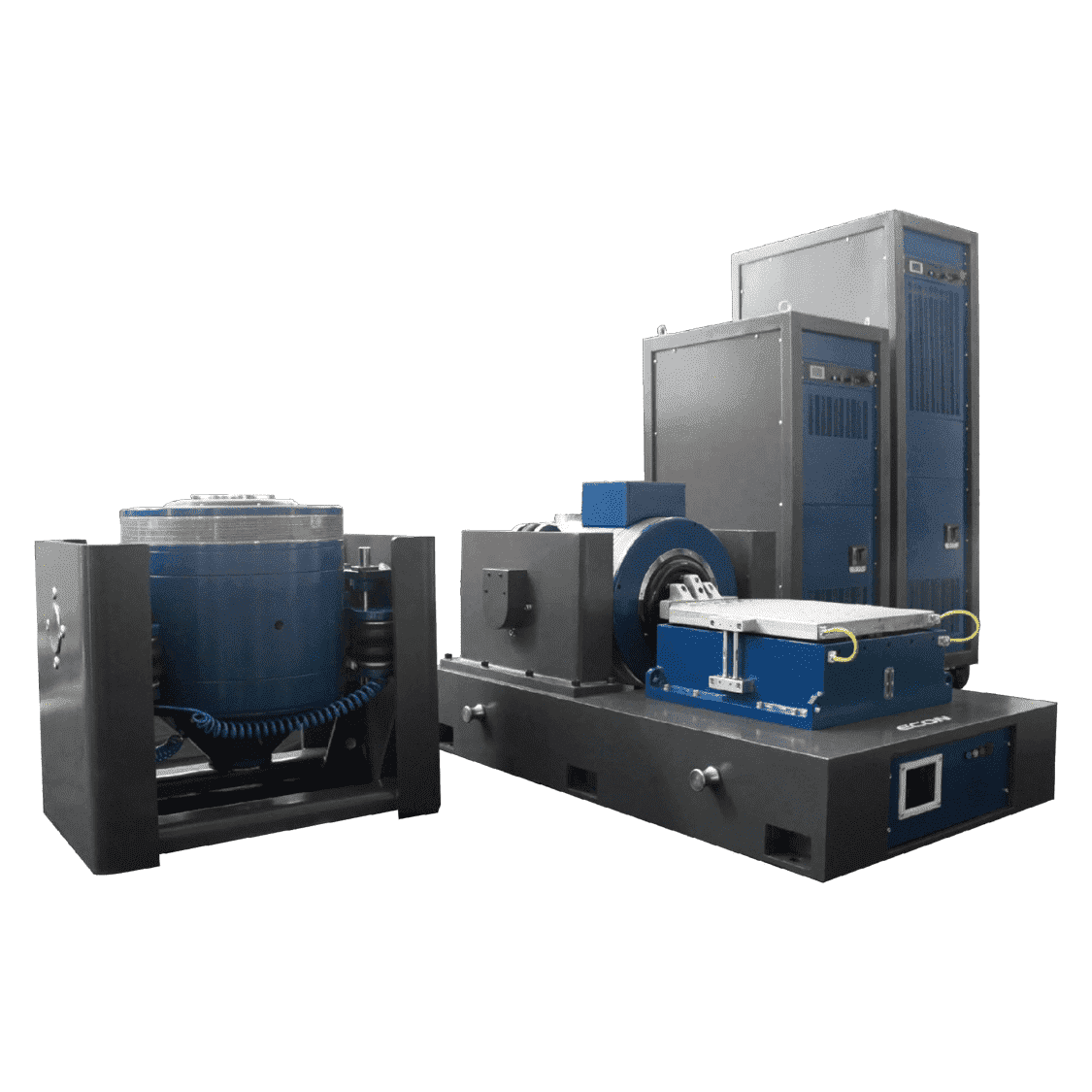

2024-08-30HUDA Environment Test Chamber Series <HUD-E703 Thermal Shock Test Chamber>

FEATURESPerfect appearance and easy to operate.Imported LCD English microcomputer temperature controller, with high memory capacity, can save 100 programs, max 9999 cycles, each cycle max time 999hrs.Two chamber structures, high temperature chamber and low temperature chamber, control automatically, stay and switch time adjustable.Perfect protection alarm functions: short-circuits, Leakage, over temperature of work chamber; compressor over pressure, over load, short water…Control interface will display alarm reason and provide check methods, machine has emergency stop button.Cold and hot shock temperature recover within1 minute, which complies with MTL, IEC, JIS, GJB and other international standards.ReadMore -

2024-08-30

2024-08-30HUDA Environment Test Chamber Series <HUD-E714 AltitudeTest Chamber>

The core of the simulated high-altitude low-pressure test chamber is that it can create and maintain a low-pressure atmosphere similar to the high-altitude environment. Through a vacuum pump or compressor system, the gas inside the test chamber is extracted or compressed to achieve the required low-pressure conditions. At the same time, in order to simulate the real high-altitude environment, the test chamber must also have the ability to accurately control environmental parameters such as temperature and humidity to ensure the comprehensiveness and accuracy of the test. In addition, some high-end models also integrate composite environmental simulation functions such as vibration and shock to further simulate the performance of products in complex space environments.Technical features1. High-precision control: Modern simulated high-altitude low-pressure test chambers use advanced control systems, which can achieve precise control of environmental parameters such as air pressure, temperature, and humidity, with extremely small error ranges, ensuring the accuracy of test results.2. Wide range of adjustment: In order to meet the testing needs of different products, the test chamber has a wide range of air pressure adjustment, from near vacuum to near standard atmospheric pressure, and parameters such as temperature and humidity also have a wide range of adjustment capabilities.3. Safe and reliable: The test chamber is designed with complete safety protection measures, such as overpressure protection, overcurrent protection, leakage protection, etc., to ensure the safety of personnel and equipment during the test.4. Easy to operate and maintain: The friendly human-machine interface and intelligent operating system make the operation of the test chamber simple and fast, and the modular design facilitates later maintenance.ReadMore -

2024-11-07

2024-11-07Huda Participated in FILM & TAPE EXPO 2024 (Shenzhen,China)

Exhibition InformationExhibition Hall: Shenzhen International Convention and Exhibition Center (Bao'an New Hall) Time: November 6-8, 2024 Booth No.: 12A61Huda' s Testing Machines at the ExhibitionHUD-E702 Programmable Constant Temperature and Humidity Test Chamber HUD-B609B-S Computer Servo Tensile Testing Machine HUD-C005 Sample Cutting Board HUD-C524-6 Normal Temperature Adhesive Tape Retention Tester HUD-C526 Adhesive Tape Initial Adhesion Tester HUD-C527-6 Constant Temperature Adhesive Tape Retention Tester Huda has joined hands with this event for the third time in a row to explore the infinite possibilities of the film and tape industry. Here, every moment is a discovery, and every communication may open a new chapter of cooperation. We look forward to meeting you at the exhibition site, sharing wisdom and drawing a blueprint for the industry together!ReadMore -

2024-09-29

2024-09-29HUDA Tensile Testing Series for Rubber Raw Materials & Products

Industry Background Rubber products are widely used in construction, automobiles, medical treatment, electronics and other fields, so their quality and performance directly affect the safety and reliability of the products. Possible problems with rubber products include unqualified material composition, substandard physical properties, insufficient aging resistance, etc. These problems may lead to quality problems or safety hazards during product use. Therefore, it is very important to conduct comprehensive and accurate testing of rubber products.Test Objects1. Natural rubber: Latex, Coagulated rubber, Sheet rubber, Rrubber block;2. Synthetic rubber: Butyl rubber, Silicone rubber, Styrene-butadiene rubber (SBR), Chloroprene rubber (CR), Ethylene-propylene rubber (EPR), Polyurethane elastomer (Polyurethane), Nitrile rubber (NBR), Butanone rubber (HNBR), etc.;3. Rubber products: Tires, O-rings, Sealing rings, Sealing pads, Rubber pipes and hoses, Rubber pads and rubber gaskets, Rubber sealing strips, Rubber floors, Rubber gloves, Rubber cables and wire sleeves, Rubber pipe fittings, Rubber anti-vibration pads, Rubber bearings, Rubber floor coatings, Rubber molds, Rubber boat pads, Rubber grinding wheels, etc.HUDA tensile test machine series can macth rubber physical properties test. Such as tensile strength, bending strength, tearing performance,peel strength, shear strength and other tests.HUDA tensile test machine series: HUD-B604-S/HUD-B609B-S/HUD-B615-S/HUD-B617-SReadMore -

2024-09-29

2024-09-29HUDA Environment test Series for Rubber Raw Materials & Products

Industry Background Rubber products are widely used in construction, automobiles, medical treatment, electronics and other fields, so their quality and performance directly affect the safety and reliability of the products. Possible problems with rubber products include unqualified material composition, substandard physical properties, insufficient aging resistance, etc. These problems may lead to quality problems or safety hazards during product use. Therefore, it is very important to conduct comprehensive and accurate testing of rubber products.Test Objects1. Natural rubber: Latex, Coagulated rubber, Sheet rubber, Rrubber block;2. Synthetic rubber: Butyl rubber, Silicone rubber, Styrene-butadiene rubber (SBR), Chloroprene rubber (CR), Ethylene-propylene rubber (EPR), Polyurethane elastomer (Polyurethane), Nitrile rubber (NBR), Butanone rubber (HNBR), etc.;3. Rubber products: Tires, O-rings, Sealing rings, Sealing pads, Rubber pipes and hoses, Rubber pads and rubber gaskets, Rubber sealing strips, Rubber floors, Rubber gloves, Rubber cables and wire sleeves, Rubber pipe fittings, Rubber anti-vibration pads, Rubber bearings, Rubber floor coatings, Rubber molds, Rubber boat pads, Rubber grinding wheels, etc.HUDA environment test chamber series can macth rubber weather resistance test: Xenon lamp/UV aging, High-low temperature performance, Salt spray test, Ozone aging resistance, etc.HUDA environment test chamber series: HUD-E702 climate chamber/HUD-E703 thermal shock test chamber/HUD-E708 Rapid-rate thermal cycle chamber/HUD-E710 ip test chamber/HUD-E801 ozone aging test chamber/HUD-E808 salt spray test chamber/HUD-E704 Anti-yellow aging test chamber/HUD-E802 uv weathering test chamber/HUD-E711 xenon weathering test chamber.ReadMore -

2024-09-29

2024-09-29HUDA IP Test Series

In modern life, electronic devices have become an indispensable part of our daily lives. However, in harsh environmental conditions, factors such as dust, water, and oil pollution may damage the equipment, affecting its service life and performance. In order to meet these challenges, the International Electrotechnical Commission (IEC) has developed the IP protection level standard to evaluate the protection of electrical equipment against solid foreign objects and liquid intrusion.The "IP protection level" consists of two numbers. The first number indicates the dustproof level, and the second number indicates the waterproof level. The larger the number, the stronger the protection.Dust protection level0: No dust protectionIP1X: Prevents intrusion of solid foreign objects with a diameter greater than 50 mmIP2X: Prevents intrusion of solid foreign objects with a diameter greater than 12.5 mmIP3X: Prevents intrusion of solid foreign objects with a diameter greater than 2.5 mmIP4X: Prevents intrusion of solid foreign objects with a diameter greater than 1 mmIP5X: Prevents intrusion of dust IP6X: Completely dustproofWaterproof level0: No waterproof protectionIPX1: Protected against vertical drippingIPX2: Protected against dripping within 15°IPX3: Protected against jetting waterIPX4: Protected against splashing waterIPX5: Protected against low-pressure water column (within 3 minutes, 12.5 cm from the nozzle, spray with a φ12.5 mm water column at a 30° tilt)IPX6: Protected against strong jetting waterIPX7: Protected against short-term immersion in water (depth not exceeding 1 m, time not exceeding 30 minutes)IPX8: Protected against long-term immersion in water (depth exceeding 1 m)IPX9K: Protected against high-temperature and high-pressure water column (80°C hot water sprayed at a flow rate of 17.5 L/min at a distance of 10 cm from the nozzle for 15 minutes)Application Areas1、Industrial control equipment: usually works under harsh environmental conditions such as dust, oil, high temperature, high humidity, etc., so it is necessary to select equipment with a high IP protection level to ensure its normal operation.2、Household appliances: such as washing machines, air conditioners, etc., also need to consider dust and water resistance. For example, washing machines need to prevent water splashing, while air conditioners need to prevent dust from entering.3、Outdoor lighting equipment: It is exposed to wind and rain for a long time, so it is necessary to choose equipment with a high IP protection level to ensure its durability.ReadMore -

2024-09-29

2024-09-29HUDA Aging Test Chamber Series

Product Types Tested in Aging ChambersPlastic and rubber products: Tires, seals, conveyor belts, pipes and other materials are easily affected by factors such as light, temperature, and humidity during long-term use, and may experience aging, discoloration, cracking and other problems;Electronic and electrical: Solar panels, LED lamps, electronic components and other electronic products often need to withstand high temperature, high humidity, ultraviolet rays and other environmental tests;Metal and alloy materials: Copper, aluminum, iron, steel alloy, aluminum alloy, copper alloy and other metal materials are prone to corrosion in humid, salt spray and other environments;Paints and coatings: Paints, varnishes, anti-corrosion coatings and other coatings play an important role in protecting substrates from environmental erosion.Aging Chambers Applications:1、HUD-E801 ozone aging test chamber: mainly used to simulate high-concentration ozone environment and evaluate the aging performance of materials under the action of ozone.Suitable industries: rubber, plastic, wire and cable industries, and fields with high requirements for material weather resistance.2、HUD-E802 uv aging test chamber: simulates ultraviolet radiation in sunlight to test the light aging resistance of materials.Suitable industries: products or materials used outdoors such as coatings, plastics, automobiles, and building materials.3、HUD-E711 xenon lamp aging test chamber: can simulate multiple environmental factors at the same time, such as sunlight, rain, temperature, humidity, etc., to conduct comprehensive light and thermal radiation aging tests on materials.Suitable industries: automobile, construction, coatings, plastics and other industries, which need to evaluate the durability of materials in actual use environments.4、HUD-E704 yellowing resistance aging test chamber: different exposure time and temperature conditions can be set to simulate different use environments.Suitable industries: plastics, rubber, coatings, inks, electronics, automobiles, etc., used to evaluate the yellowing resistance of materials under light conditions.5、HUD-E808 salt spray test chamber: mainly used to simulate the marine and salt spray environment to test the corrosion resistance of materials.Suitable industries: automobiles, ships, electronics, aerospace, etc., fields that require the corrosion resistance of products.ReadMore -

2024-10-31

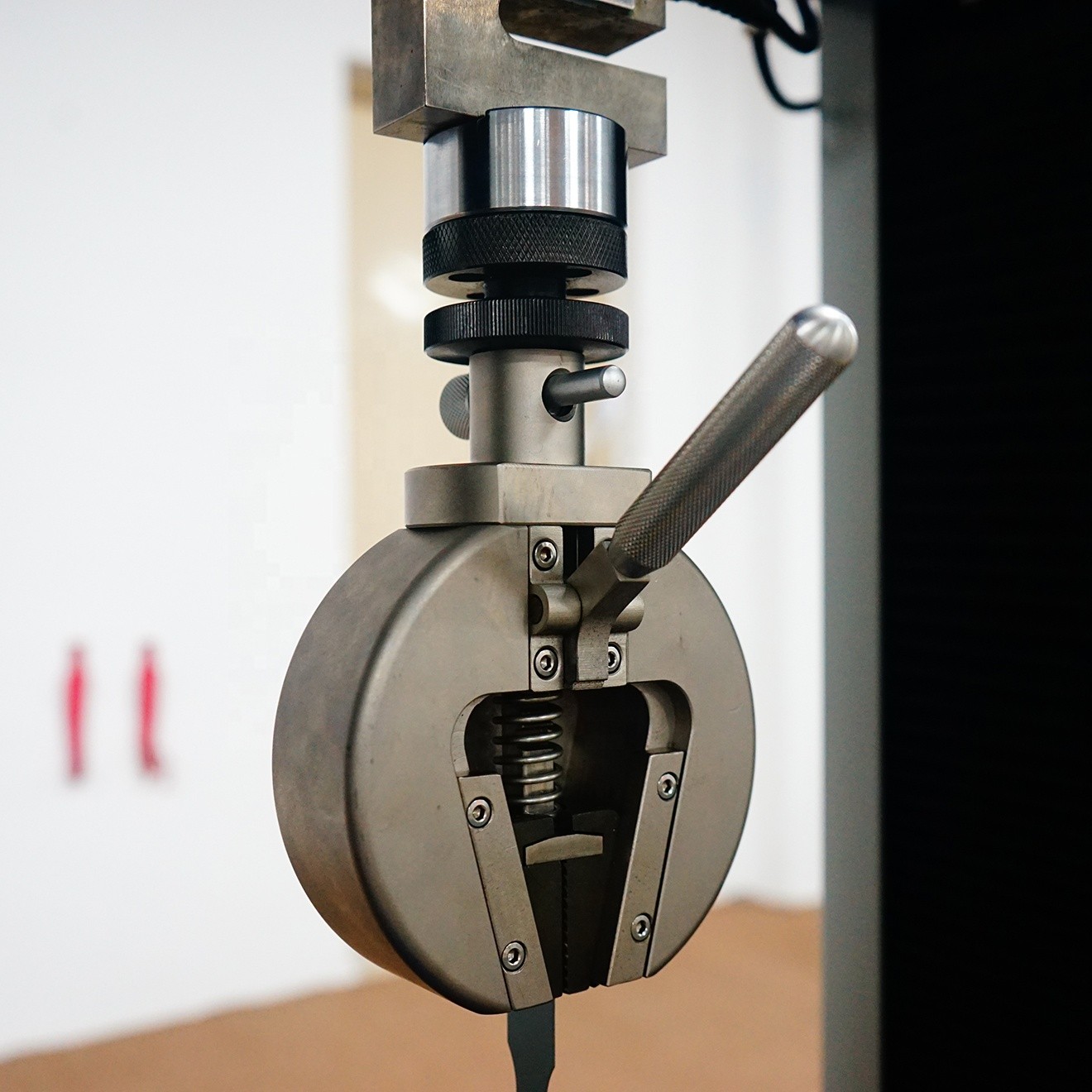

2024-10-31How to Choose the Clamp for the Tensile Testing Machine

How to accurately select the tensile machine fixture depends on the shape of the material and sample being tested. The following are the steps to select the fixture:Determine the size, shape, and physical properties of the material being tested. For example, sheet, wire, rubber, etc.Select the appropriate fixture type based on the characteristics of the sample. Common fixture types on the market include but are not limited to peeling fixtures, aluminum plane fixtures, parallel fixtures, bending fixtures, large deformation fixtures, etc.Consider the clamping method according to needs, such as manual clamping, pneumatic clamping, etc., which can directly affect the convenience of testing and the accuracy of results.Make sure the size of the grips is appropriate for the sample size to avoid unstable clamping due to the grips being too large, or damaging the sample due to the grips being too small.The grip material should be chosen to be compatible with the sample material to avoid damage to the sample or affecting the test results.Flexibly selecting appropriate fixture accessories according to test requirements, such as extension fixtures, winding fixtures, etc., can help you better cope with complex test scenarios. In the process of selecting tensile machines and their supporting fixtures, whether it is material strength verification or product durability testing, HUDA company has a professional team that can provide you with the best testing solution to ensure that the selected fixture fully meets the test requirements and ensure the accuracy of the test.ReadMore -

2024-10-31

2024-10-31How to Choose a Tensile Testing Machine

How to choose a tensile testing machine of high quality? We need to focus on the following two dimensions:Precision Precision refers to the accuracy of the measurement results, that is, the degree of closeness between the measured value and the true value. In the application of tensile testing machines, higher precision means that the performance parameters of the material can be measured more accurately. In order to improve the accuracy of the test, it is usually necessary to select equipment with high resolution, so that more detailed data changes can be obtained, thereby more accurately evaluating the mechanical properties of the material.Range The range refers to the maximum force range that a tensile testing machine can measure. When selecting a tensile testing machine, the range should be selected based on the expected strength range of the material being tested. If the range is too large, it may result in inaccurate measurements within a small force range; while if the range is too small, it may not meet the testing requirements of materials with a large force range. There is a balance between accuracy and range. Generally speaking, the smaller the range, the higher the accuracy and resolution of the device, because the device can make more detailed measurements within a smaller force range. However, if the force range of the sample exceeds the selected range, then the measurement cannot be performed. Therefore, when choosing a tensile testing machine, it is necessary to balance the relationship between accuracy and range according to the actual test needs to ensure that the accuracy requirements can be met without limiting the scope of the test due to insufficient range.In summary, facing the needs of different customers in the market, HUDA provides a series of products for everyone to choose from.ReadMore

+86-769-89201493 / 135 0966 8705