-

2023-11-06

2023-11-06ISTA Transportation Vibration Tester Ensuring Product Safety on the Go

Transportation Vibration Tester is to simulate the goods in transit, encounter different road conditions such as bumpy, uphill, downhill, cornering, etc., products in the car produce the collision between goods and goods or goods and car and the extrusion between goods.With a the packaging vibration test, you can ensure the packaging comply to international requirement (like ISTA) and avoid damage during transit. Understanding the Role of ISTA Transportation Vibration Tester:The ISTA Transportation Vibration Tester is designed to replicate the vibrations products experience during transportation, such as those caused by road conditions, air travel, or train journeys. It simulates the real-world operational environment, allowing manufacturers to evaluate how their products perform and sustain themselves while being transported from one location to another.Key to Testing Products:1. Evaluating the Impact on Quality: One of the primary objectives of the ISTA Transportation Vibration Tester is to evaluate the impact of vibrations on the overall quality and performance of a product. By subjecting the product to various vibration amplitudes, frequencies, and durations, manufacturers can identify weaknesses, address potential damage risks, and make necessary improvements to prevent product spoilage or failures.2. Identifying Vulnerable Points: Different products have distinct weaknesses that can be exposed during transportation. The ISTA Transportation Vibration Tester allows manufacturers to identify and address these vulnerability points. By pinpointing areas prone to failure and implementing modifications accordingly, they can significantly enhance their product's durability, safety, and reliability.3. Saving Time and Costs: Without proper testing, products may fail during transportation, leading to increased costs for manufacturers, distributors, and end customers. By utilizing the ISTA Transportation Vibration Tester, manufacturers can identify potential failure points before products are shipped, avoiding costly and time-consuming issues down the line. This proactive approach not only saves money but also helps prevent customer dissatisfaction and potential damage to the brand's reputation.The ISTA Transportation Vibration Tester plays an indispensable role in the shipping industry by ensuring that products can endure the vibrations encountered during transportation. By subjecting products to realistic simulations, manufacturers can enhance their product's quality, identify weaknesses, and prevent potential failures. Investing in testing equipment like the ISTA Transportation Vibration Tester helps businesses foster customer satisfaction, protect their brand reputation, and ultimately establish a strong foothold in the competitive market where safe and reliable products are essential.ReadMore -

2023-11-29

2023-11-29The Vital Role of Upgrading the Battery Nail Penetration Test Chamber for Product Testing

Innovation and safety are two key aspects when it comes to the manufacturing industry, particularly in the production of electronic devices. As technology advances, so does the need for more effective and reliable testing methods to ensure the safety of these products. One crucial component in this process is the Battery Nail Penetration Test Chamber, which plays a crucial role in determining the safety standards of batteries used in various electronic devices. In this blog post, we'll explore the significance of upgrading this chamber to provide customers with better and safer product testing.Before delving into the importance of this upgrade, let's first understand the purpose of the Battery Nail Penetration Test Chamber. This chamber simulates real-life scenarios where batteries may accidentally come into contact with sharp objects, such as nail punctures. By subjecting the batteries to controlled conditions that mimic potential accidents, manufacturers can evaluate the safety and resilience of their battery designs. This testing is essential to prevent any potential risks, such as leakage, explosion, or fire hazards, caused by battery failures in everyday use.Now, why is it necessary to upgrade the Battery Nail Penetration Test Chamber for customers? Firstly, technological advancements have made it possible to develop batteries with greater energy densities and improved chemical compositions. However, traditional testing chambers may not be equipped to handle these new battery designs adequately. Upgrading the chamber would ensure that customers are using the most advanced testing equipment, capable of accurately simulating real-life scenarios.Secondly, regularly updating the testing chambers allows for a more comprehensive evaluation of battery safety. As new research and knowledge are acquired, regulations and safety standards evolve accordingly. Customers need access to upgraded equipment that aligns with the latest safety requirements to ensure their products meet or exceed these standards.Lastly, investing in the upgrade of the Battery Nail Penetration Test Chamber would enhance customer satisfaction. By providing them with the latest testing capabilities, manufacturers can instill confidence in their products, reassuring consumers that their safety is a top priority. It also reflects positively on the industry as a whole, showcasing its commitment to delivering safe and reliable electronic devices.In conclusion, upgrading the Battery Nail Penetration Test Chamber is imperative to ensure thorough and accurate testing of batteries used in electronic devices. The advancement of technology, the need for strict safety standards, and customer satisfaction all necessitate the utilization of the most up-to-date testing equipment available. By investing in this upgrade, manufacturers can guarantee the safety and reliability of their products, ultimately benefiting both businesses and consumers alike.ReadMore -

2024-01-08

2024-01-08Ensuring Battery Safety with HUDA Technolo’s Battery Test Chambers

When it comes to the efficiency and safety of batteries, testing under various conditions is crucial. This is where battery test chambers come into play, providing a controlled environment for testing the performance and safety of batteries. At HUDA Technolo, we specialize in supplying top-quality battery test chambers designed to meet the specific testing needs of various types of batteries.Our battery test chambers are equipped to simulate a wide range of environmental conditions, including low and high temperatures, humidity changes, vibration changes, and altitude changes. This comprehensive testing capability allows for a thorough assessment of battery performance in real-world scenarios, ensuring that they meet the necessary safety and quality standards.One of the key focuses of our battery test chambers is on ensuring battery safety. We understand the importance of adhering to international safety standards, and our chambers are designed to conform to IEC, UL, and EUCAR testing standards for battery safety. This means that when you use our test chambers, you can have confidence in the accuracy of the results and the safety of the testing process.Our chambers are suitable for testing a variety of battery types, including Lithium Ion batteries, lead acid, Battery Managements Systems (BMS), battery packs, modules, and battery cells. This flexibility makes them an ideal choice for manufacturers and researchers working with different battery technologies.In addition to providing a controlled testing environment, our battery test chambers also incorporate numerous safety features to prevent any potential hazards during the testing process. This includes features such as temperature and pressure control, emergency shut-off systems, and built-in safety protocols.At HUDA Technolo, we are committed to ensuring that our battery test chambers meet the highest standards of safety, reliability, and performance. Whether you are conducting research on battery technologies or manufacturing batteries for commercial use, our test chambers are the ideal choice to ensure the safety and quality of your products. Contact us today to learn more about our battery test chambers and how they can benefit your battery testing needs.ReadMore -

2024-01-12

2024-01-12Battery Burning Test Chamber

The Battery Burning Test Chamber is specifically designed for the flame resistance test of lithium batteries or battery packs. This crucial piece of equipment is used to simulate the extreme conditions that batteries may be exposed to, such as high temperatures and fire. By subjecting the batteries to these harsh environments, the test chamber can evaluate their performance and safety features.One of the key benefits of the Battery Burning Test Chamber is its ability to identify potential hazards before the batteries are put into use. This proactive approach allows manufacturers to address any safety concerns and make necessary improvements to their products. Additionally, it provides peace of mind to consumers, knowing that the batteries they are using have undergone rigorous testing to ensure their safety.The importance of this testing equipment cannot be overstated, especially when considering the potential risks associated with lithium batteries. In recent years, there have been numerous reports of battery-related incidents, including fires and explosions. By utilizing the Battery Burning Test Chamber, manufacturers can mitigate these risks and prevent such incidents from occurring.Furthermore, the Battery Burning Test Chamber plays a crucial role in compliance with industry standards and regulatory requirements. As safety regulations become increasingly stringent, it is essential for manufacturers to demonstrate that their products meet the necessary safety standards. By conducting thorough flame resistance tests using the test chamber, manufacturers can ensure that their batteries are in compliance with these regulations.ReadMore -

2024-02-29

2024-02-29Battery Crush Test Chamber: Ensuring the Safety of Batteries

The Battery Crush Test Chamber is a vital tool in ensuring the safety and reliability of various types of batteries. It is designed to simulate the squeezing of batteries that may occur during their use, transportation, storage, or disposal of household waste. This test is crucial in determining whether a battery is qualified for safe usage without experiencing any catastrophic failure.The importance of this test chamber cannot be overstated, especially in the current era where batteries are an integral part of our daily lives. From the batteries in our smartphones and laptops to the ones used in electric vehicles and renewable energy storage systems, ensuring their safety is of utmost importance.The Battery Crush Test Chamber works by subjecting the batteries to a controlled amount of pressure, simulating the conditions they may encounter in real-world scenarios. This is important because, during their lifecycle, batteries may be exposed to forces that could cause them to deform or rupture. By testing them in a controlled environment, manufacturers can evaluate their performance and make necessary improvements to ensure their safety.A battery is considered qualified if it does not explode, catch fire, leak, or vent gas when subjected to the pressure in the test chamber. This ensures that the battery will not pose a risk to the users, whether in consumer electronics or industrial applications.Furthermore, the test also helps in identifying potential design flaws in the batteries, enabling manufacturers to make necessary modifications to improve their safety and reliability. This is particularly important as new battery technologies emerge, and manufacturers strive to develop more efficient and safer products.ReadMore -

2024-04-25

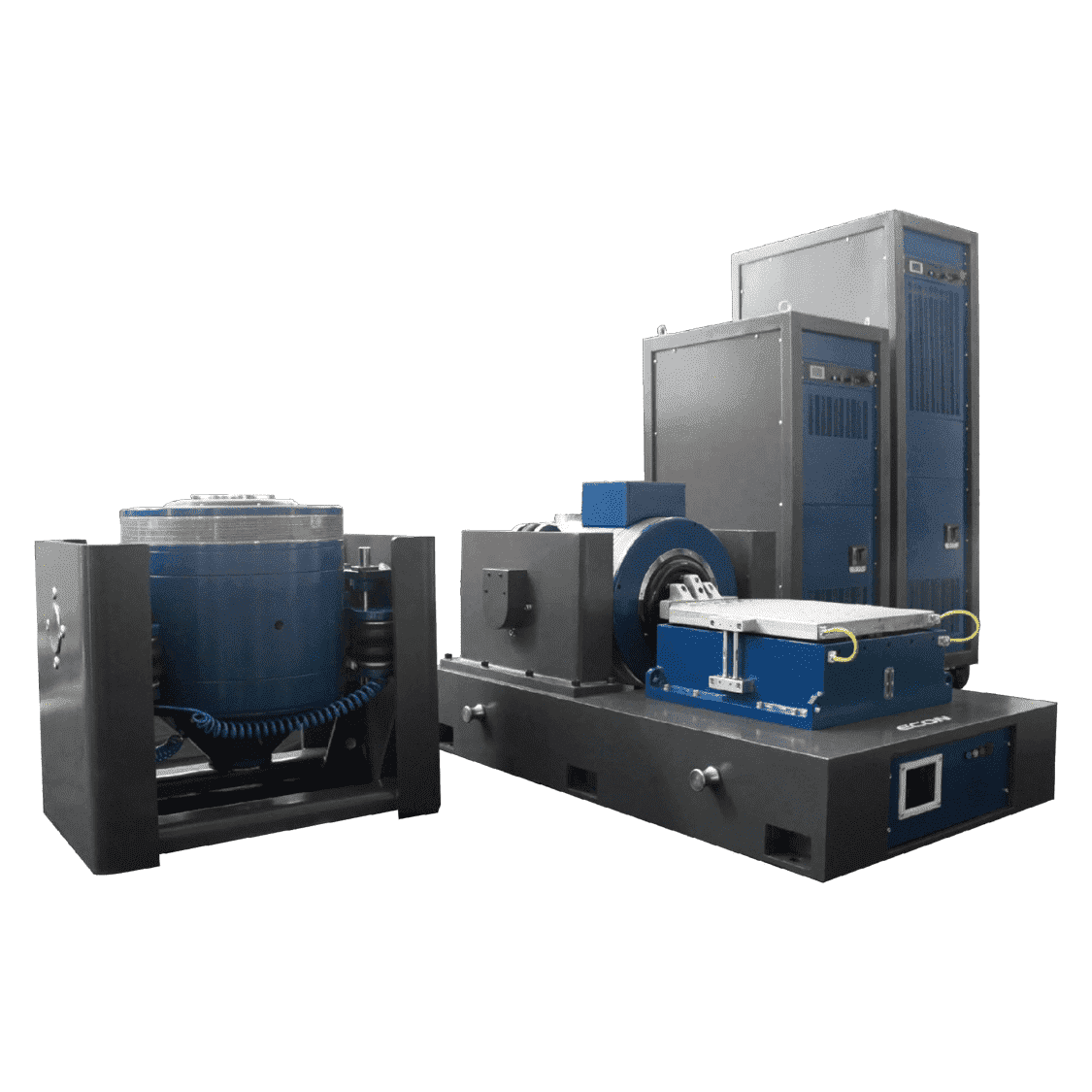

2024-04-25Single-axis Vibration Test Systems

Single-axis vibration test systems are used to simulate real-world vibrations that products may experience during transportation, operation, or other environmental conditions. These systems typically consist of a vibration table or platform onto which the test specimen is mounted, along with one or more actuators or shakers that produce controlled vibrations along a single axis.Here's how they generally work:Test Specimen Mounting: The item or product to be tested is securely mounted onto the vibration table or platform. This ensures that it experiences the vibrations accurately and without damage.Actuators or Shakers: These are the components responsible for generating vibrations. They are typically electromechanical devices capable of producing controlled oscillations along a single axis. The amplitude, frequency, and waveform of the vibrations can be adjusted as per the testing requirements.Control System: A control system governs the operation of the vibration test system. It allows the user to set parameters such as vibration amplitude, frequency, duration, and waveform. Advanced control systems may also incorporate feedback mechanisms to ensure precise control and monitoring of the vibrations.Data Acquisition: During the test, various sensors may be used to measure and record data such as vibration levels, frequency response, and structural integrity of the test specimen. This data is crucial for evaluating the performance and durability of the product under vibration conditions.Applications of single-axis vibration test systems include:Product Reliability Testing: Ensuring that products can withstand vibrations encountered during transportation, handling, or operation.Quality Control: Verifying the quality and durability of components and assemblies subjected to vibration.Research and Development: Studying the effects of vibration on materials, structures, and systems to improve product design and performance.Regulatory Compliance: Meeting industry standards and regulations that require products to undergo vibration testing to ensure safety and reliability.These systems are widely used in industries such as automotive, aerospace, electronics, and consumer goods to assess the robustness and reliability of products before they are brought to market.ReadMore -

2024-06-26

2024-06-26HUDA——New Solution for Battrey test <HUD-G809 Battery Shock Impact Test System>

Application:Battery Shock Impact Test System is a fully automatic pneumatic lifting vertical shock test system. It is used to measure and determine the impact resistance of products or packaging, and assess the functional reliability and structural integrity of the test product in a shock environment. Mechanical Shock Test System can perform various conventional classic shock tests to realize the shock wave and shock energy that the product is subjected to in the actual environment, thereby improving the system or optimizing the structure of the product. It is vertical shock test equipment with novel design, high degree of automation, simple operation and convenient maintenance. Features:a) Windows-based stable control system: fully automatic remote-control interface, the operator only needs to input simple values, the IPS-2000 shock control & measuring instrument can accurately complete the shock test;b) Full pneumatic drive shock, clean and environmentally friendly, simple structure and high reliabilityc) Pneumatic drive greatly improves the shock test efficiency, maximum shock rate up to 120 times / mind) The shock rate can be controlled by adjusting the gas pressure, and the shock rate can be continuously adjustede) High-performance cast aluminum table: cast aluminum table has high strength and hardness, as well as a higher first-order resonance frequency, low noise, and no clutter;f) Complete measurement system: various waveform tolerance bands are stored in the system, which is convenient for users to adjust and apply, and automatically complete the test report generation after the test is completed;g) The controller has functions of door protection, runaway protection and zero signal protection to ensure the safety of the system.h) Dual-guide pillar: combined with pneumatic balance lifting system, no noise, fully automatic positioning table;i) Convenient installation: The equipment comes with a high-performance buffer and vibration isolation device, no special foundation is required, and the installation is convenient, safe and reliable.ReadMore -

2024-06-26

2024-06-26HUDA——New Solution for Battrey test<HUD-H204 Battery Altitude Test Chamber>

Application: Battery Altitude Simulation Test Chamber is designed for UL, EN, IEC and other standard test requirements. It can reach the low-pressure storage state of the sample in a short time. It can automatically control the test cycle, monitor the air pressure change in the chamber during the whole process, and realize the automatic termination of the test.ReadMore -

2024-08-30

2024-08-30HUDA Environment Test Chamber Series <HUD-E702 Climate Chamber>

It can simulate environment and test electronic instruments, new materials, electrical, vehicles, metals, electronic products, aerospace materials, etc. may encounter during transportation, storage, and use; or in high temperature, low temperature, hot and humid environments, to test the high temperature resistance, cold resistance, hot and humid performance of materials, accessories or instruments and equipment and the possible damage and shortened lifespan.Comply with below standards:1.GB2423.1-2008/IEC6008-2-1-20072.GB/T 2423.2-20083.GJB150.3A-20094.GJB150.4A-20095.GB2423.22-20086.GBT 2424.5-20067.GB/T 10589-20088.GB/T2423.3-2008(IEC68-2-3)ReadMore

+86-769-89201493 / 135 0966 8705