Specifications

| No | Description | Specifications | ||

| 1 | Model | HUD-B616 | ||

| 2 | Max. load | 300KN | 600KN | 1000KN |

| Load range | 6KN-300KN | 12KN-600KN | 20KN-1000KN | |

| Load accuracy | ±1% | |||

| Elongation resolution | 0.01mm | |||

| Piston stroke | 250mm | |||

| Max. piston stroke speed | 50mm/min | |||

| 3 | Elongation accuracy | ±1% | ||

| 4 | Max. Tensile space | 300mm(excluding piston stroke) | ||

| 5 | Max. Compression space | 250mm(excluding piston stroke) | ||

| 6 | Display mode | PC | ||

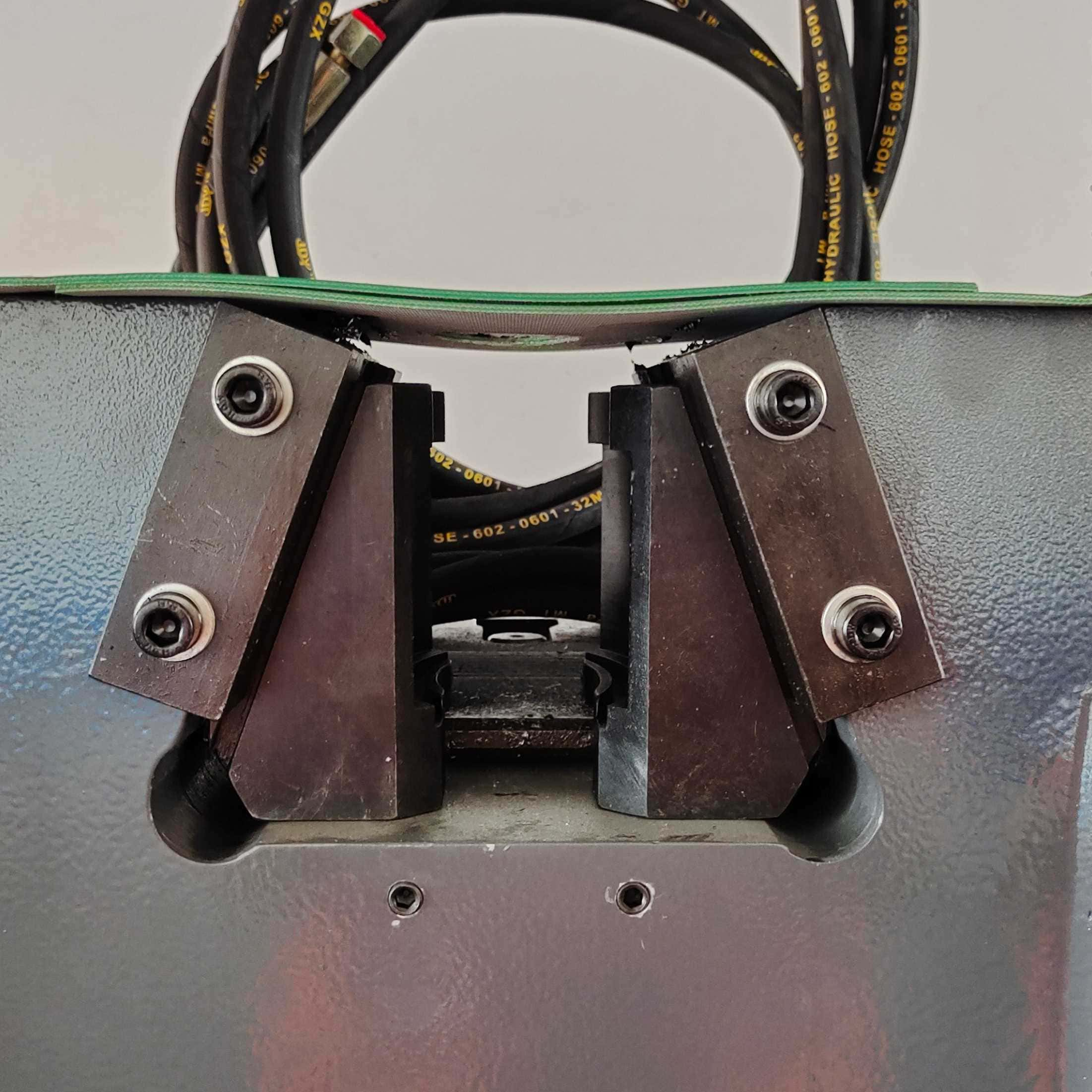

| 7 | Clamping mode | Hydraulic | ||

| 8 | Operation mode | Manual | ||

| 9 | Flat sample thickness | 0-15 mm | ||

| 10 | Clamping width | 70mm | 70mm | 125mm |

| 11 | Round sample diameter | Φ10-φ32 mm | Φ13-φ40 mm | Φ13-φ60 mm |

| 12 | Compression plate size | 170*170mm | 170*170mm | 204*204mm |

| 13 | Load frame dimensions | 900*750*2200mm | ||

| 14 | Oil source dimensions | 1200 x 550 x 1100mm | ||

Test Standard

ISO6892, BS4449,ASTM C39,ISO75001, ASTM A370, ASTM E4, ASTM E8 and BSEN standards

Features

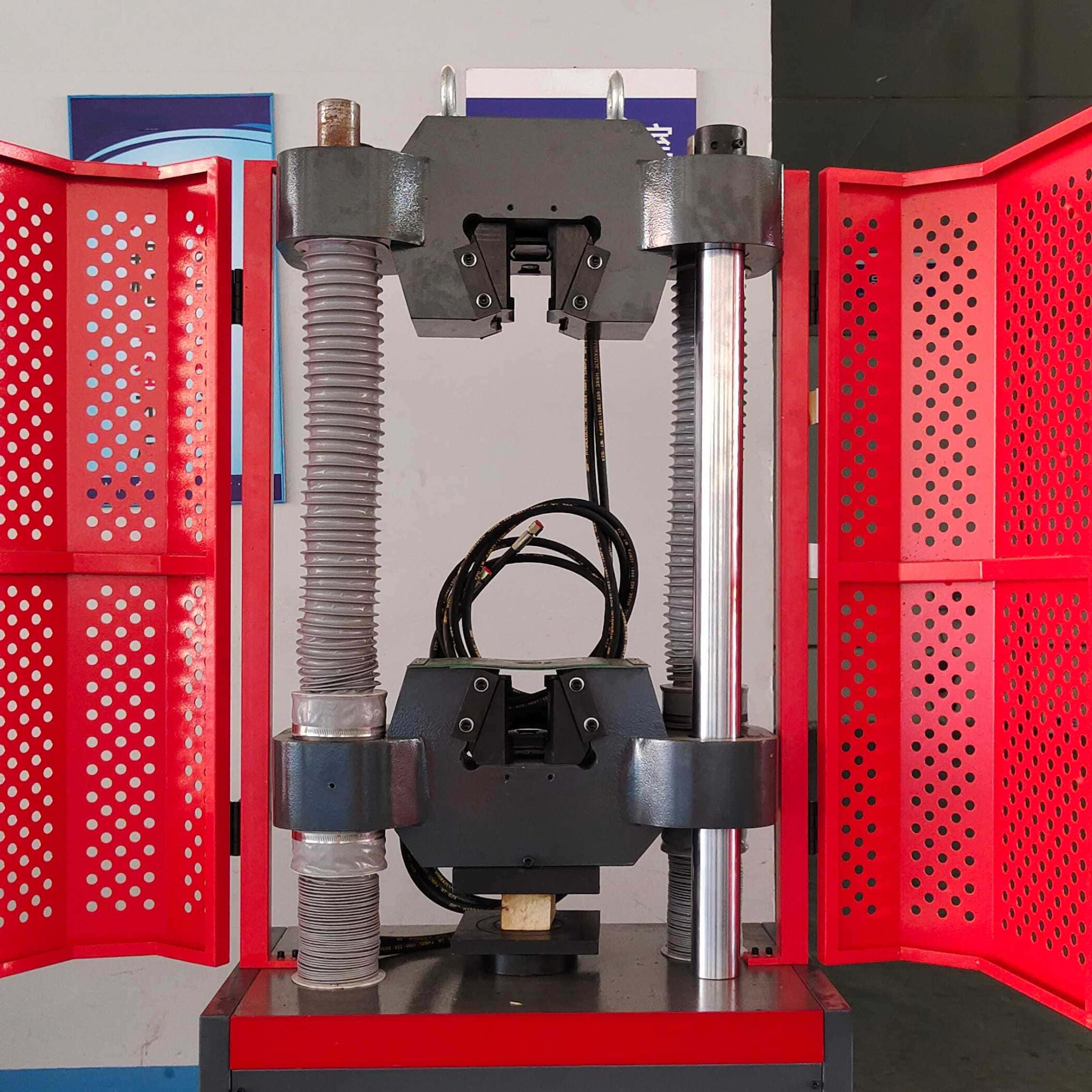

Dual power mechanism servo motor gear pump.Dual motors, dual oil pumps, gear oil pump for boosting. The separate oil supply of the clamp and the oil cylinder is stable and reliable. (The traditional three-phase asynchronous motor supplies oil for the clamp, and the servo motor supplies oil for the oil cylinder. It is ultra-quiet and the noise is less than 70 decibels. The loading is more stable and faster. The sample clamping is more reliable and durable.)

●New external independent controller

The addition of an independent external manual control unit provides a new solution for the measurement, control and operation of the testing machine. USB data transmission fully supports notebook computers, tablet computers, and desktop computers; it is an important part of leading the development of testing machine technology;

●Higher stability, stronger rigidity and better durability.

●Multifunctional handheld controller

It can control the rise and fall of the moving beam and the oil cylinder, the clamping and unclamping of the jaws, and the emergency stop function of the oil pump, which is more convenient to use the sample clamping;

●Equipment operation monitoring system

It has the function of phase sequence, phase loss self-check indication, electrical overcurrent, overload and other protection functions, so that the equipment operation is safe and reliable;

●The upper and lower jaw seats of the main machine adopt the wedge

Shaped clamping method - the sample is more stable, and the sample fracture is more neutral;

●The lower part of the lead screw is equipped with an elastic damping mechanism

Effectively reducing the impact caused by the fracture of the sample and reducing the noise;

●A flexible dust cover is added to the outside of the lead screw

Prevent foreign objects from entering, to increase the durability of the lead screw and transmission mechanism, and to improve the aesthetics of the whole machine;

●Safety shield

Three-sided cold-rolled steel plate punching safety shield to prevent foreign objects from flying out during the test. It improves the protection level and facilitates real-time observation by operators, effectively ensuring the personal safety of the experimenter.

●The servo pump station adopts the cartridge valve type differential pressure follow-up technology

It is energy-saving, environmentally friendly, safe and reliable, and reduces the heating of the system; at the same time, the clamping force increases with the increase of the test force, and the sample is firmly clamped.

Standards

SPECIFICATION

| test | 1 | 2 |

| test | 1 | 2 |

| test | 1 | 2 |

| test | 1 | 2 |

| test | 1 | 2 |

| test | 1 | 2 |

| test | 1 | 2 |

| test | 2 | 2 |

DETAILS

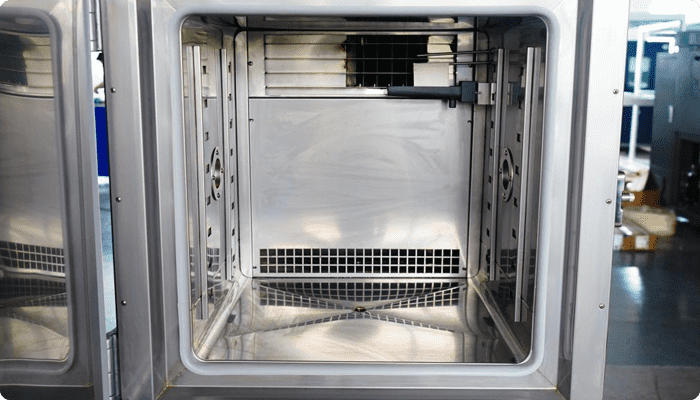

Inner Chamber

Outer wall: 1.5mm cold-rolled steel plate with plastic-sprayed surface;

Insulation layer: 100mm polyurethane foam + ultra-fine glass wool, to ensure that the outer surface of the test box does not frost and dew;

Inner wall: 1.2mmSUS304 # stainless steel plate;

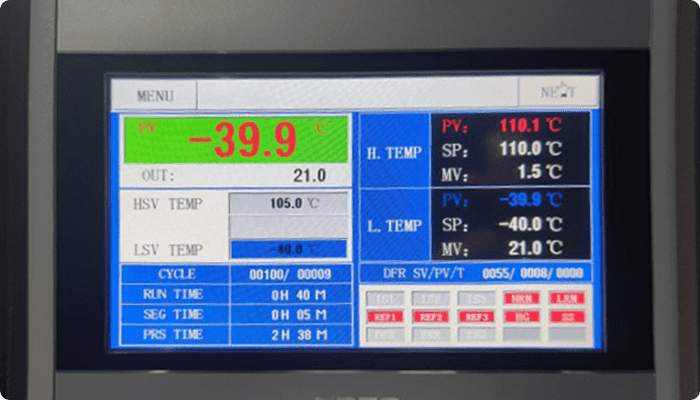

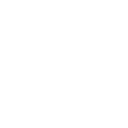

Control system

7 ”TFT color touch screen controller

P.I.D control parameters: 9 sets of PID control parameters are automatically calculated

Screen functions Touch input, display temperature and humidity set value and measured value, display various parameters of program operation, operation timing, display equipment operation curve and history curve, Chinese and English interface optional, fault prompt screen, screen backlight adjustable.

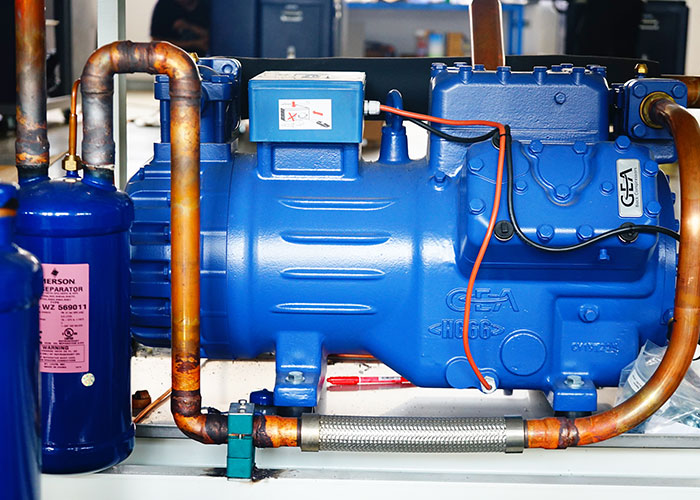

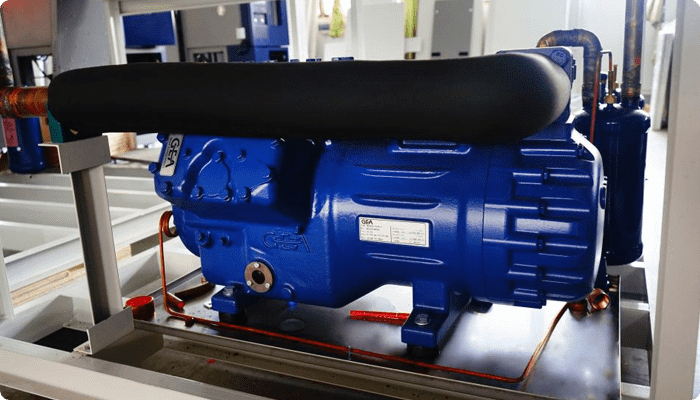

Refrigeration System

Mechanical compression refrigeration;

Compressor starts at the suitable time, reducing the compressor starting current and reducing the interference to the power grid;

The controller + solenoid valve on and off to control the refrigerant flow for cold balance control;

No cooling during heating, no heating during cooling, because the cooling balance method can reduce the consumption of compressor and heating system, and theoretically can save 20% or more energy at low temperature;

Humidity System

Water circuit separation to ensure safety

Safety System

1 over temperature alarm

2 leakage protection

3 over current protection

4 lack of phase protection

5 overpressure protection

6 grounding protection

7 water shortage protection

8 gas shortage protection

Electrical System

Wiring neatly, all components with a label to show its function