Specifications

Item | Specification |

Load capacity | 5-2000kg (50N,100N,200N,500N,1kN,2kN,5kN,10kN,20kN,can be optional) |

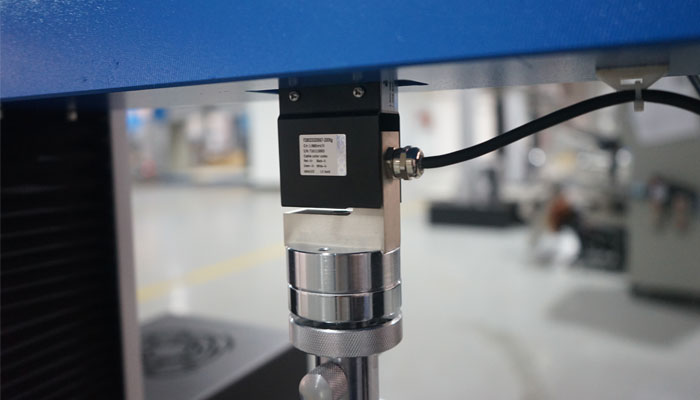

Load cell brand | Imported brand load cell |

Motor | Panasonic servo motor |

Driver | 400w Panasonic driver |

Screw | High precision ball screw |

Control system | Computer control, Windows 7 or 10 system |

Test speed | 0.1-500mm/min(Adjustable) |

Stroke | 1200mm (Including clamp) |

Load resolution | 1/250,000 |

Load accuracy | ≤0.5% |

Unit | gf/kgf/N//kN/LBf/T |

Dimension | (L*W*H)880*505*1470mm |

Weight | Approx 183.9 KG |

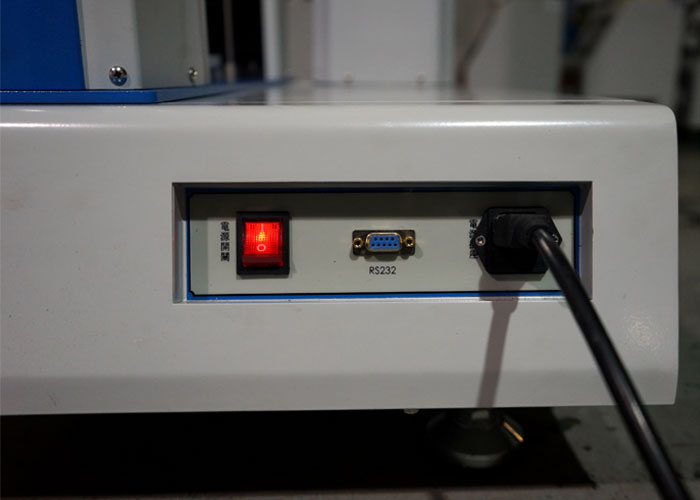

Power | 1∮ AC 220V |

Features

FEATURES

integrates multiple independent testing functions such as tensile, deformation, peeling, tearing, and compression, and provides a variety of test items for users to choose;

provide data analysis of constant tensile stress, elastic modulus, stress and strain;

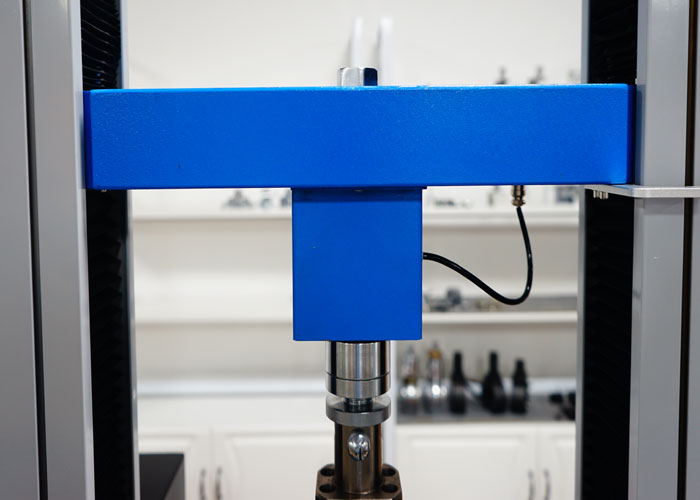

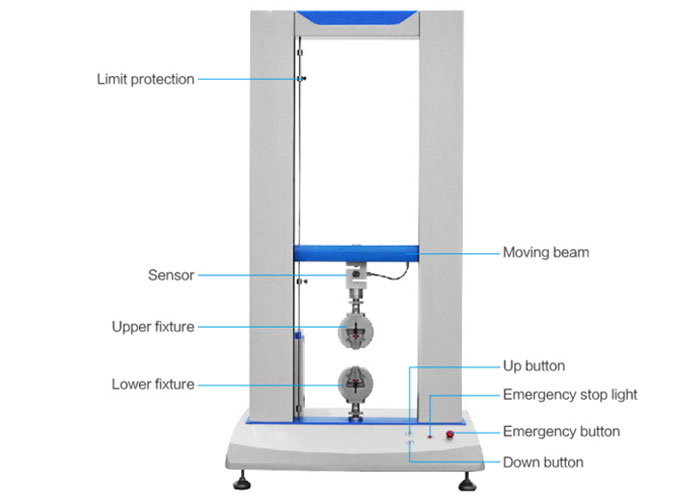

double-pillar ball nut and screw drive to ensure high precision and smooth operation;

FEATURES

the equipment adopts miniaturization and structural integration design, which can meet the test requirements of various occasions;

1~500mm/min stepless speed change, which provides convenience for users to test under different test conditions;

intelligent configuration such as multi-level limit protection, overload protection, automatic high-speed return, and fault notification to ensure the user's operation safety;

FEATURES

embedded system and membrane key switch, which are convenient for users to conduct test operations quickly;

the embedded control system effectively guarantees the security of the system and improves the reliability of data management and test operations;

the system is equipped with 4 usb ports and 2 network ports to facilitate data transmission and external access of the system;

professional software provides statistical analysis of group test curve overlay analysis, maximum, minimum, average, and standard deviation.

FEATURES

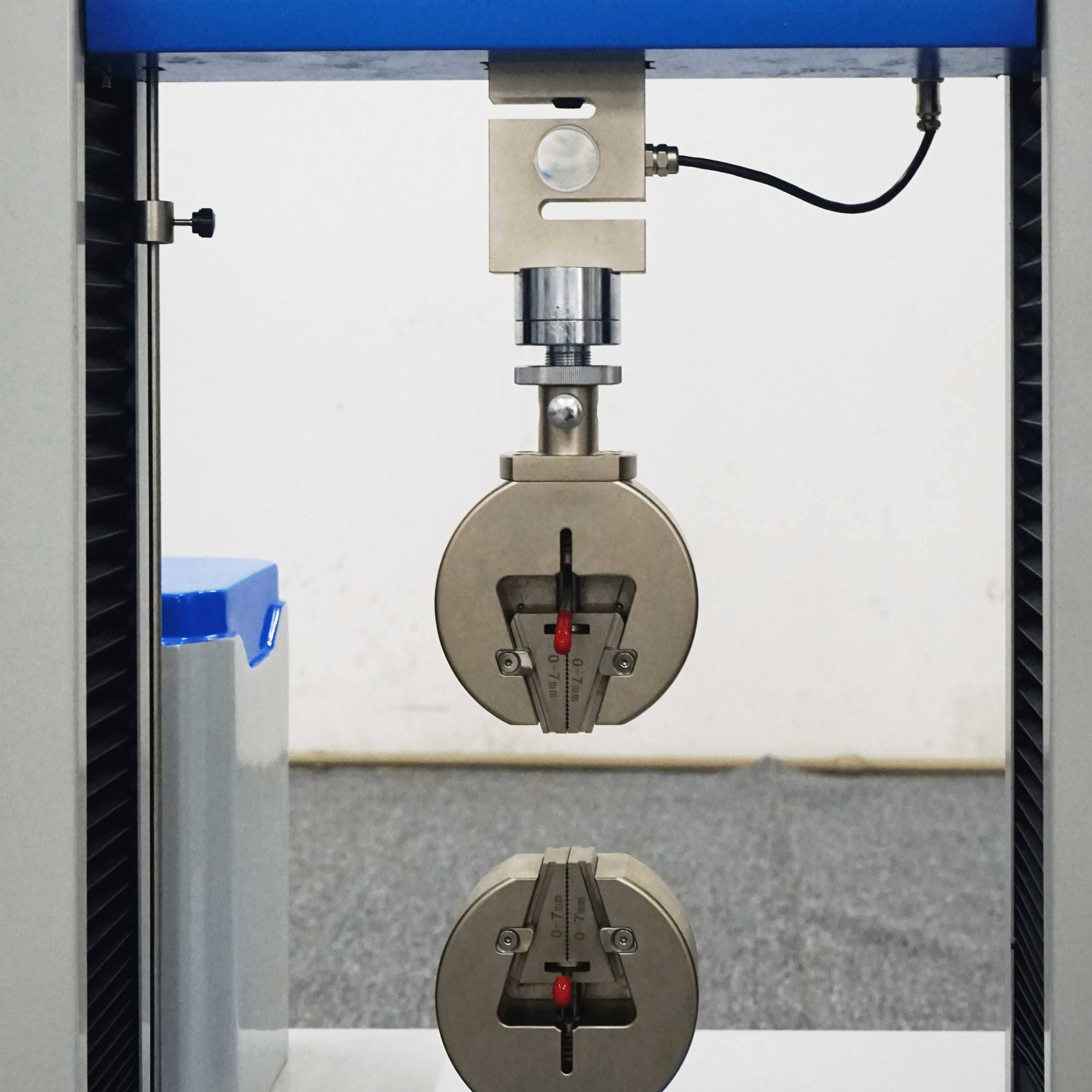

equipped with more than 100 different sample fixtures for choose.

meet the test requirements of more than 1000 kinds of materials.

according to the different testing materials, huda also provides customized services to meet the testing needs of different customers.

Structures

Applications

|

Basic application |

Extended application (Need special accessories or restructuring) |

|||

|

Tensile strength and deformation rate |

Breaking force of ampoule |

Film puncture force |

Puncture force of lid of infusion bag with lid |

Puncture/pulling force of soft rubber stopper |

|

Breaking force |

Combination cover opening force |

ZD bottle cap tearing force |

Oral fluid lid tearing force |

Oral fluid cap puncture/pulling force |

|

Heat seal strength |

Pulling force of infusion bag cover inclined at 90 degrees |

Pull-out force of lid for infusion bag with lid |

23 degree tilting cap pulling force |

Piercing/pulling force with bottle cap and stopper |

|

Tear resistance |

90 degree peel force of tape |

Perfect bound pages tearing force |

90 degree water-based plaster peeling force |

Adhesive tearing force |

|

180 degree peel |

Adhesive strength test (soft) |

Adhesive strength test (hard) |

Peeling force of hose cap |

Catheter and catheter joint disengagement force |

|

90 degree peel |

Makeup brush bristles pulling force |

Toothbrush bristles pulling force |

Rope breaking force |

Jelly cup and yogurt cup opening force |

|

Fixed tensile test |

Milk cup cup film peeling force |

Extraction force of rubber plug |

45 degree peeling force of bottle film |

Ziplock bag mouth pull force |

|

Down test |

Magnetic card core peeling force |

90 degree peeling force of magnetic card |

Heat-sealing film tearing force |

Protective film separation force |

|

Puncture retention |

Release paper separation force |

Trouser tearing force |

Unwinding force of tape |

Pressure resistance of plastic bottles |