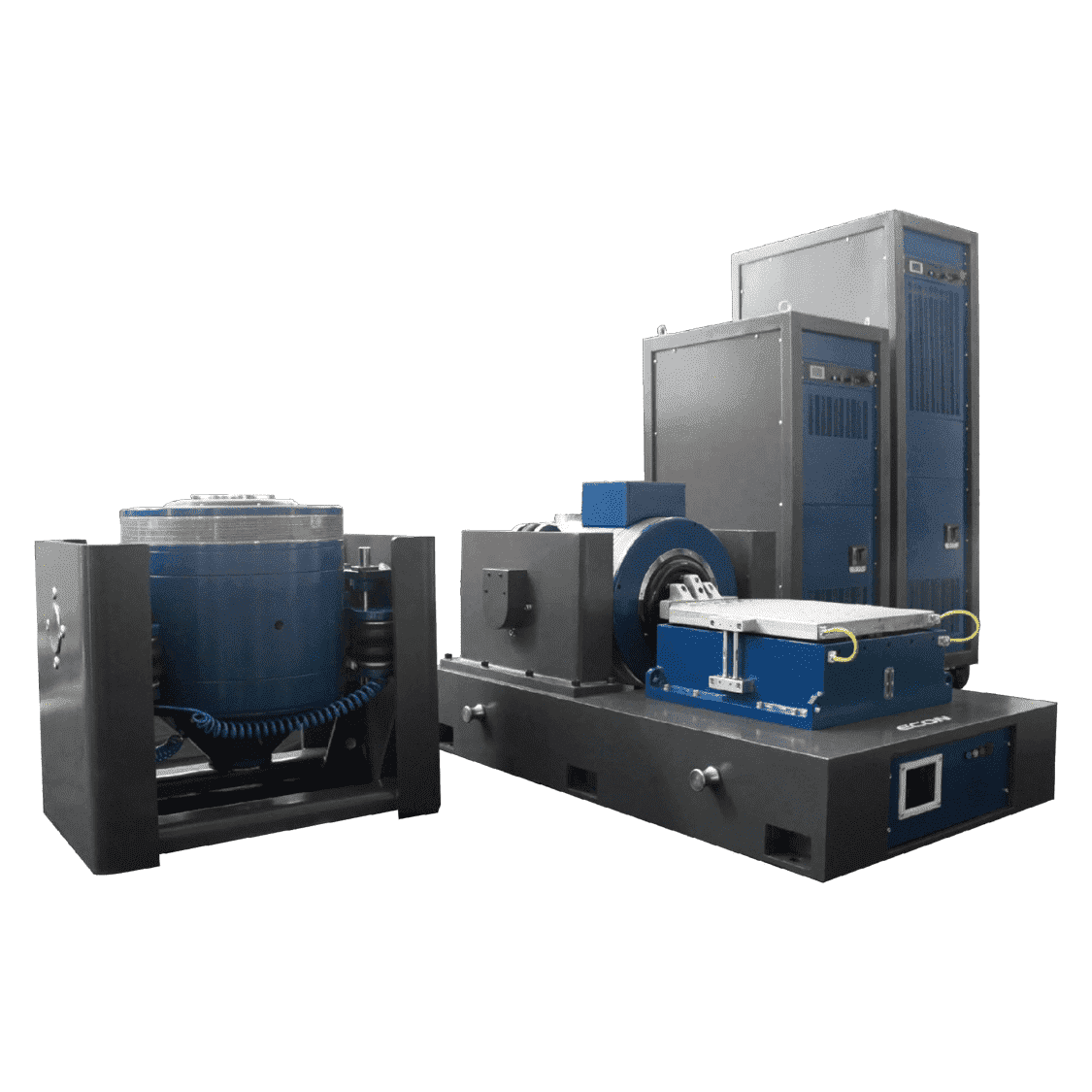

Standards

Specification Parameters

| Model | HUD-E702-100 | HUD-E702-150 | HUD-E702-250 | HUD-E702-250 | HUD-E702-1000 |

|---|---|---|---|---|---|

| Internal Dimension | 400*500*500mm | 500*600*500mm | 500*750*600mm | 600*850*800mm | 1000*1000*1000mm |

| External Dimension | 740*1700*1380mm | 870*1800*1430mm | 870*1890*1530mm | 1070*1900*1630mm | 1240*1970*2230mm |

| Temperature Range | -60℃/-40℃/-20℃~+150℃ | ||||

| Temperature Fluctuations | ≤±0.5℃(without load and temperature stable) | ||||

| Temperature Uniformity | ≤4℃(without load and temperature stable) | ||||

| Temperature Deviation | ≤±2℃(without load and temperature stable) | ||||

| Heating Rate | +25℃~+150℃≥40min(without load) | ||||

| Cooling Rate | ≤±2℃(without load and temperature stable) | ||||

| Power | 3 phase, AC380V, 50Hz, about 5KW | ||||

| Humidity Range | Temperature : +20℃~+85℃,Humidity: 20%~98%RH | ||||

| Humidity Deviation | 1、≥75%RH : ≤±3%RH;2、≤75%RH:≤±5%RH | ||||

| Noise | ≤ 75db, measured from one meter in front of door, at 1.2meter height | ||||

Detailed Content

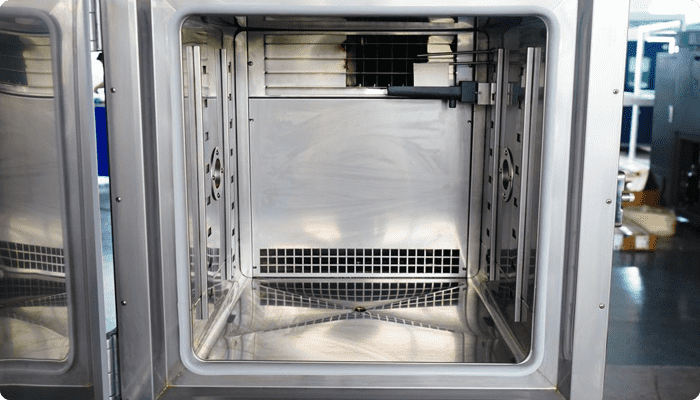

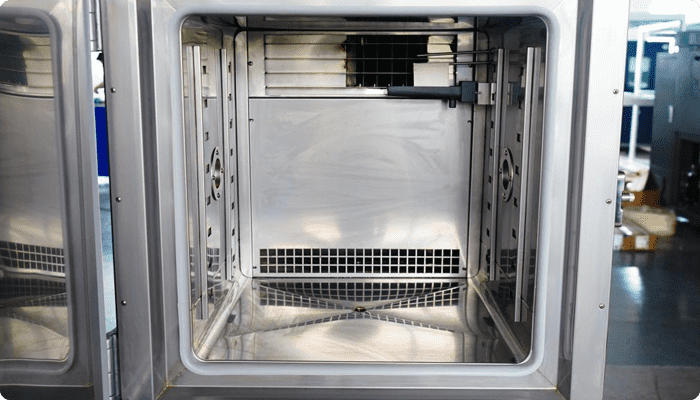

Inner Chamber

Outer wall: 1.5mm cold-rolled steel plate with plastic-sprayed surface;

Insulation layer: 100mm polyurethane foam + ultra-fine glass wool, to ensure that the outer surface of the test box does not frost and dew;

Inner wall: 1.2mmSUS304 # stainless steel plate;

Inner Chamber

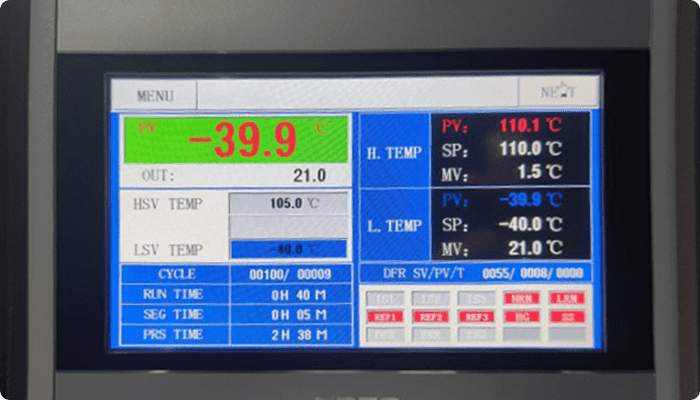

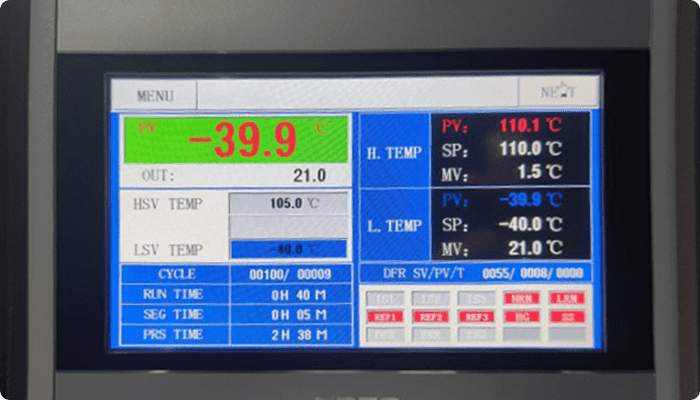

7 ”TFT color touch screen controller

P.I.D control parameters: 9 sets of PID control parameters are automatically calculated

Screen functions Touch input, display temperature and humidity set value and measured value, display various parameters of program operation, operation timing, display equipment operation curve and history curve, Chinese and English interface optional, fault prompt screen, screen backlight adjustable.

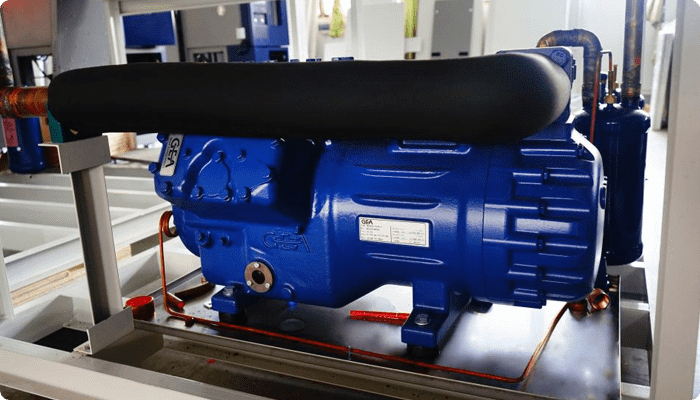

Refrigeration System

Mechanical compression refrigeration;

Compressor starts at the suitable time, reducing the compressor starting current and reducing the interference to the power grid;

The controller + solenoid valve on and off to control the refrigerant flow for cold balance control;

No cooling during heating, no heating during cooling, because the cooling balance method can reduce the consumption of compressor and heating system, and theoretically can save 20% or more energy at low temperature;

Humidity System

Water circuit separation to ensure safety

Safety System

1 over temperature alarm

2 leakage protection

3 over current protection

4 lack of phase protection

5 overpressure protection

6 grounding protection

7 water shortage protection

8 gas shortage protection

Electrical System

Wiring neatly, all components with a label to show its function

Operation Video